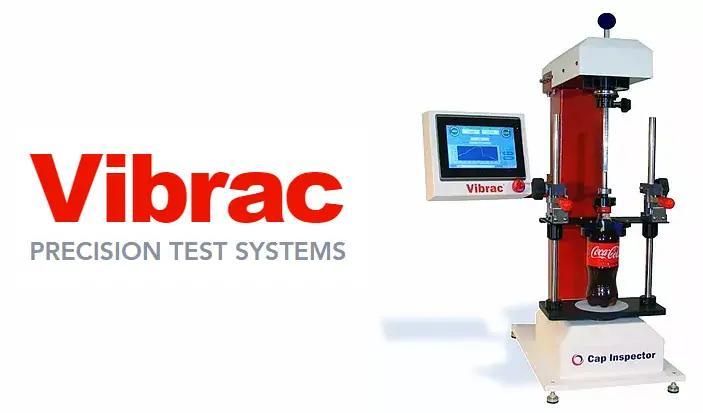

Cap Torque Inspection Solutions

Cap Torque Inspection tool has been an integral part of the packaging industry’s quality control program for years. Cap torque testing helps prevent consumer complaints from difficult-to-open products, product leakage or spoilage from loose caps during transportation. Many packaging facilities use small, manual desktop models that are inconsistent and non-repeatable due to outside variables. A […]

Cap Torque Inspection Solutions Read More »