We have a 50,000 square foot state-of-the-art manufacturing facility that can build tanks up to 1/2 inch thick, but are most proficient at building lighter gauge tanks in the 7-14 gauge range. Our facility can accommodate the construction of tanks up to 14 feet in diameter and up to 60 feet in overall height. We manufacture our own flanged and dished heads up to 10 feet diameter. Take advantage of our in-house Mixer Lab and Electropolishing capabilities.

Beer Tanks & Systems

HERO brewing systems offer superior performance at every phase, from reducing the overall brew time, increased wort clarity, and hop utilization to crank out delicious beer for decades.

JVNW Inc. has supplied equipment to over 600 breweries worldwide.

JVNW Inc. is an equipment manufacturing company which recognizes the specific needs of the microbrewery segment of the brewing industry. Our products range from individual pieces of equipment to complete turn-key systems. We can simplify for you, the complexities of the overall brewing process. Our services include brewery sizing, equipment layout, professional installation, system testing, technical assistance, and follow-up support.

Each step of the brewing process has many options. Our vessels can be designed with versatility, allowing for the brewery functions to be combined in fewer vessels for economy, or separated into several vessels for increased capacity.

Wine Tanks

Grapes love JVNW Inc. tanks.

Today, the tanks can be gentle giants featuring sophisticated monitoring systems or simple totes for the elegance of single lot fermentation.

Whether a wine tank is conical, truncated, dished or open top; all are available in 2B (mill) finish or polished stainless steel. Specialized or standard manways are the best part of any ICC Northwest Wine Tank and a great source of pride.

Dimpled heat transfer surface (HTS) allow economical cooling/heating jackets to regulate the heat of fermentation. Multiple or split jackets offer precise control.

Fittings, valves, rotating racking arms, vents, pump-over piping extensions, removable drain screens, or cap management mechanisms, are all tools apart of the winemakers magic.

Fittings are always adjusted, angled or gusseted per the winemaker’s instructions. Temperature wells are always gusseted for extra strength.

New louvered drain screen is offered as an alternative to the standard perforated screens.

Tank floors have changed dramatically in the past several years. Although flat & sloping with sump drains, dished or conical tank bottoms are still standard; new designs of steeply truncated floors have advantages when confined entry space regulations are involved.

Powder coated (painted) or stainless steel Legs/Bases are adjustable and can always accommodate fork lifts. Legs can be replaced with anchor pads for bench mounted tanks. Tank sizing specifications reflect seismic conditions. Adjustable foot pads for uneven ground surface are always constructed of stainless steel material.

Large Size Wine Tanks

Medium Size Wine Tanks

Portable Wine Tanks

Cider Tanks

Closed Top Ferment Cider Tanks

Variable Capacity Cider Tanks

Bright Conditioning Cider Tanks

Food & Beverage

JVNW Inc. manufactures a wide variety of mix tanks and storage tanks for the food, beverage, ozone and pure water industries.

Mix Vessels

JVNW Inc. mix tanks are built in a unique work cell environment. Much like an office, a small team of fabricators work on each tank from start to finish and have every tool they need to build your tanks within an arms reach. Efficiency and quality is increased by minimizing tank transport during fabrication, and having all assembly parts readily available to the fabricator. Fabricators can perform a full range of quality checks including dye penetration and hydrostatic tests without relocating the vessel.

Cosmetic Vessels

These Portable Cosmetic Vessels offer several levels of flexibility for cosmetic companies. Portable Tanks allow the customer to monitor the quality of small batches and transport the tanks from manufacturing to packaging. The tanks can be easily cleaned in one central station and expensive “hard piped” process piping, (necessary with stationary tanks), is minimized.

Pharmaceutical Vessels

Alternate Energy Vessels

Liquid biofuels are increasing in popularity, particularly as they relate to transportation. As a proven leader in this new technology; designing, through extensive research and development, innovative processing systems, vessels and mixers.

Projects have included a modular biodiesel plant constructed entirely within shipping containers.

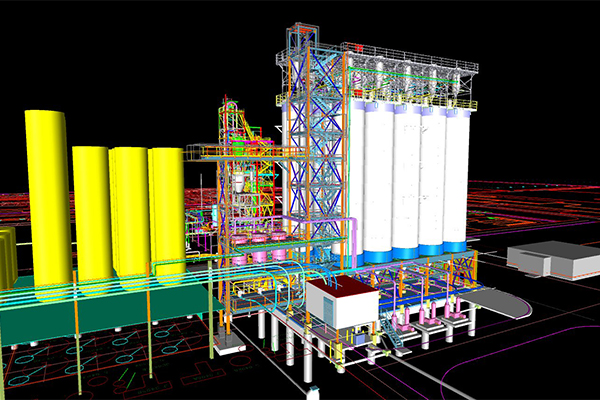

Engineering & Automation

Are you expanding and upgrading your existing facility or are you planning a new production plant? JVNW Inc. is now able to assist you with planning, design and construction.