For almost a century, Cozzoli Machine Company MRM/Elgin has provided technologically advanced machinery for the packaging industry. Cozzoli’s expertise lies in aseptic and non aseptic pharmaceutical, cosmetic, health, and beauty aids. MRM/Elgin specializes in personal care, food, beverage, chemical, paint, and industrial products. From individual machines to complete lines, we are your complete source for equipment and full service capabilities.

Cozzoli Machine Company was founded in 1919 by Frank J. Cozzoli, Sr. Originally named Modern Machine & Tool Company, the operation was located in Plainfield, New Jersey, in a building approximately 1,200 square feet. Today the Company is established in a 100,000 square foot facility in Somerset, New Jersey.

In 2010, Joan Cozzoli Rooney took over operations as President of Cozzoli Machine Company. Joan worked at CMC for many years starting at an early age. She worked closely with her father, Joseph and her brother, Frank through different areas of the company to learn the business. With her backgrounds in business administration, management and sales and marketing combined with her thorough knowledge of the product line, Joan is well equipped to lead the team at Cozzoli Machine Company MRM/Elgin.

Pharmaceutical Products

Liquid Vial Filling Machines

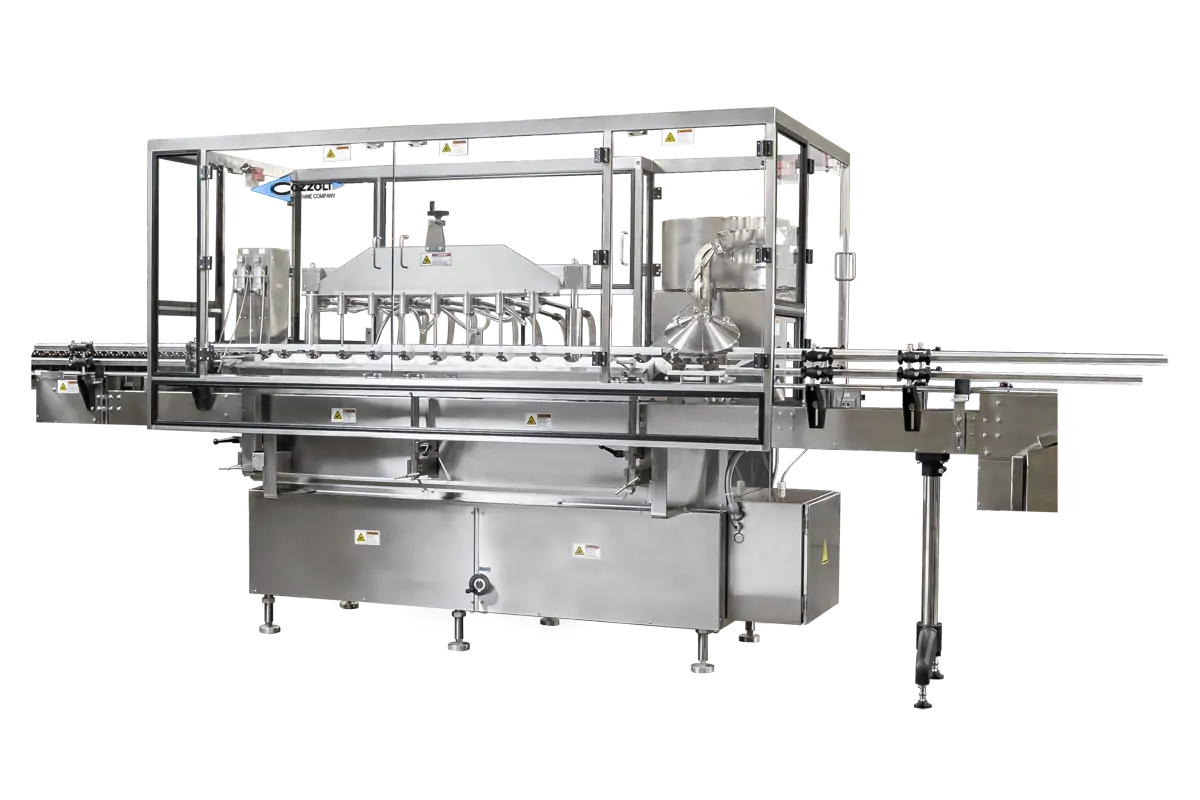

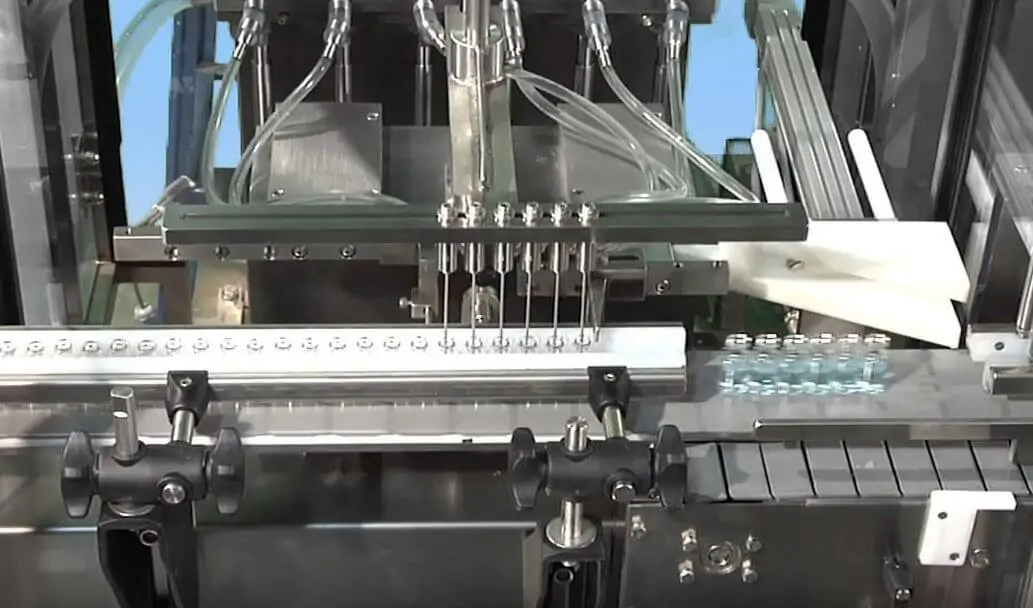

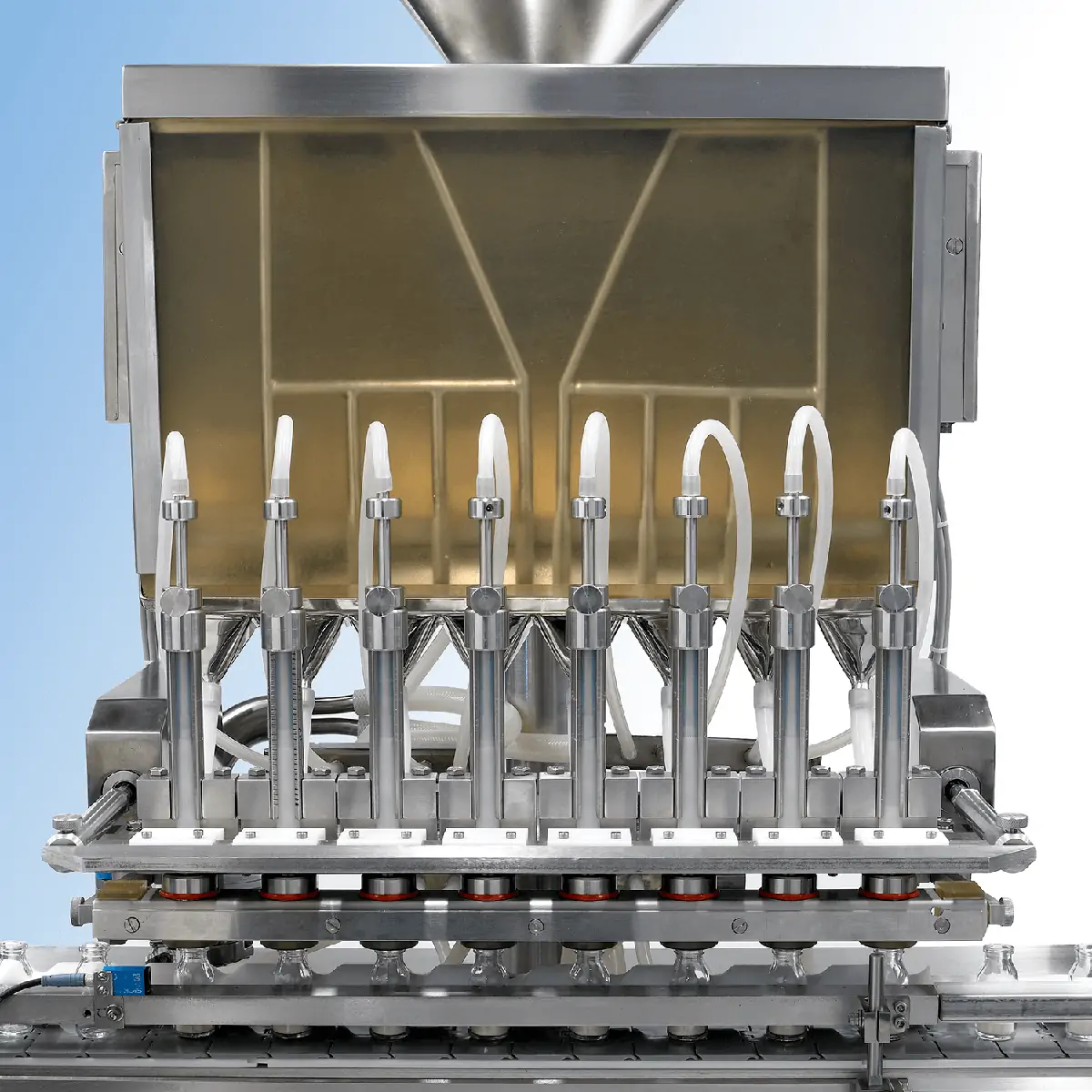

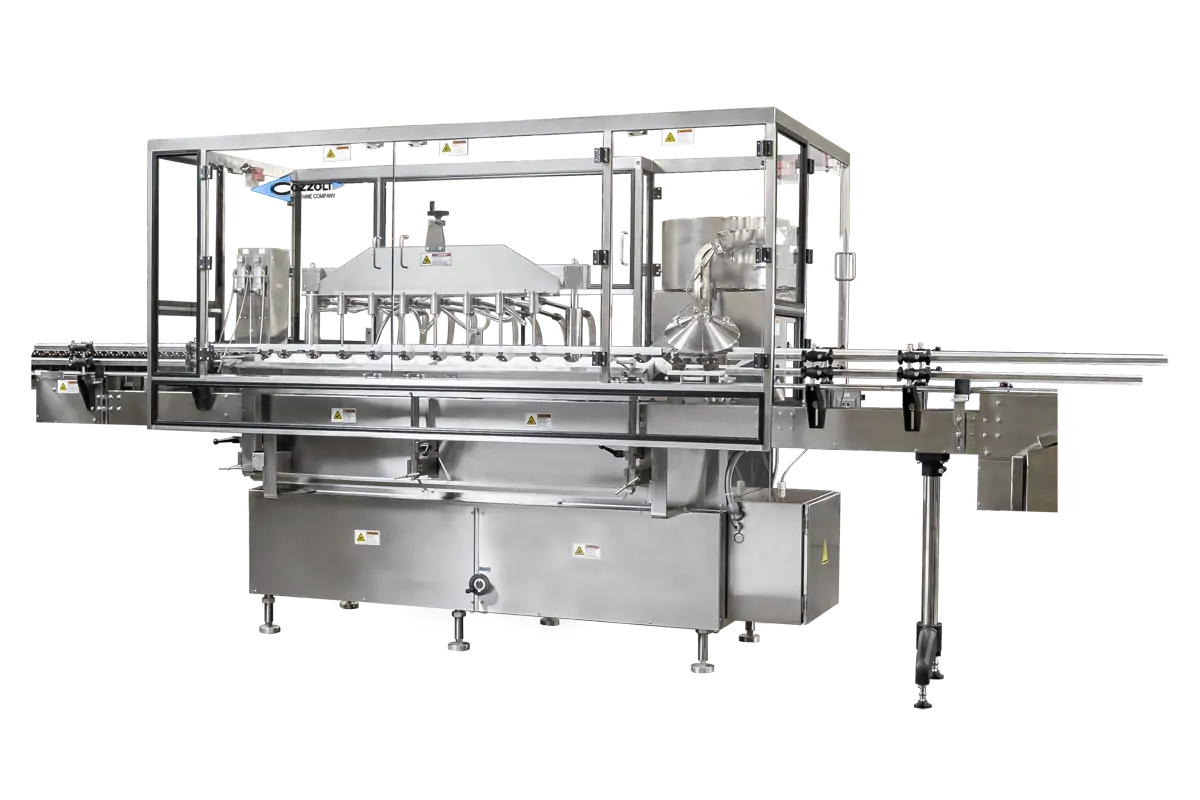

VR840 - Inline Volumetric Filler

- Optional overhead laminar air flow

- 4-16 heads

- A fill accuracy of +/- .5%,

- speeds up to 400 bpm on our VR840-16

FSV50 - Filling & Stoppering Machine

- This machine will fill liquids, then stopper the containers using full or partial stopper insertion.

- Speeds of up to 50 containers per minute with a fill accuracy of +/- .5% can be achieved with the FSV50.

RFPC - Filling, Plugging and Capping

- The RFPC series can handle various container shapes and sizes and a wide range of products from aqueous to heavy oils, suspensions and creams.

- This machine can be equipped with 1-4 nozzles and is capable of filling up to 200 vials per minute with a fill accuracy of +/- .5%.

CR Series - Filling & Stoppering Machine

- The CR Series provides continuous-motion filling and stoppering.

- Offering production speeds up to 200 and 400 containers per minute, this machine performs with outstanding fill accuracy of +/- .5% or better, with either full or partial insertion of stoppers.

VR840S - Filling & Stoppering Machine

- A fill accuracy of better than +/- .5% with speeds up to 120 bpm.

- The diving nozzle system, which uses bottom-up fill on a range of 0-6”, facilitates a quick changeover.

VR2 Series - Liquid Filling Machine

- This series can be equipped with 2-12 nozzles that fill up to 300 containers per minute, with a fill accuracy of +/- .5%.

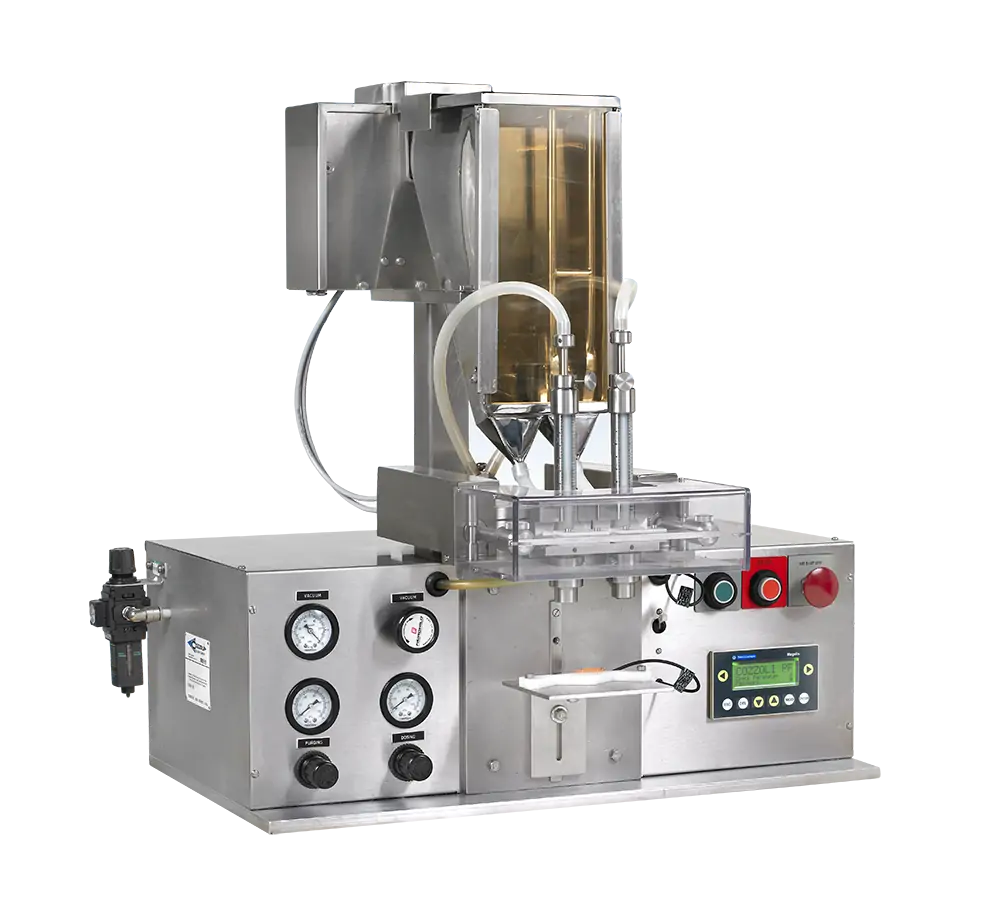

F400X - Tabletop Filler

- Perfect for low production rates with high accuracy requirements.

- Fills aqueous solutions to light oils.

- This product is shipped fully assembled and ready to use.

- Can fill up to 50 containers a minute, depending on the operator, with accuracy of +/- .5%.

Powder Filling Machines

PF - Powder Filler

- Features a unique dual-level supply hopper and agitator that provides just enough material of uniform density to supply the dosing chamber of each filling head.

- This machine can be equipped with 2-12 filling stations with a speed of up to 300 containers per minute and a fill accuracy of +/- 1%.

PF2TT/PF2IS - Tabletop Powder Filler

- Features a totally enclosed product pathway with no abrading parts ensures zero powder contamination.

- Fine tuning fill-volume adjustments can be made on the fly without tools.

- Perfect for labs or limited production facilities.

- It can be equipped with 1 or 2 filling stations that fill up to 30 containers per minute with a fill accuracy of +/- 1%.

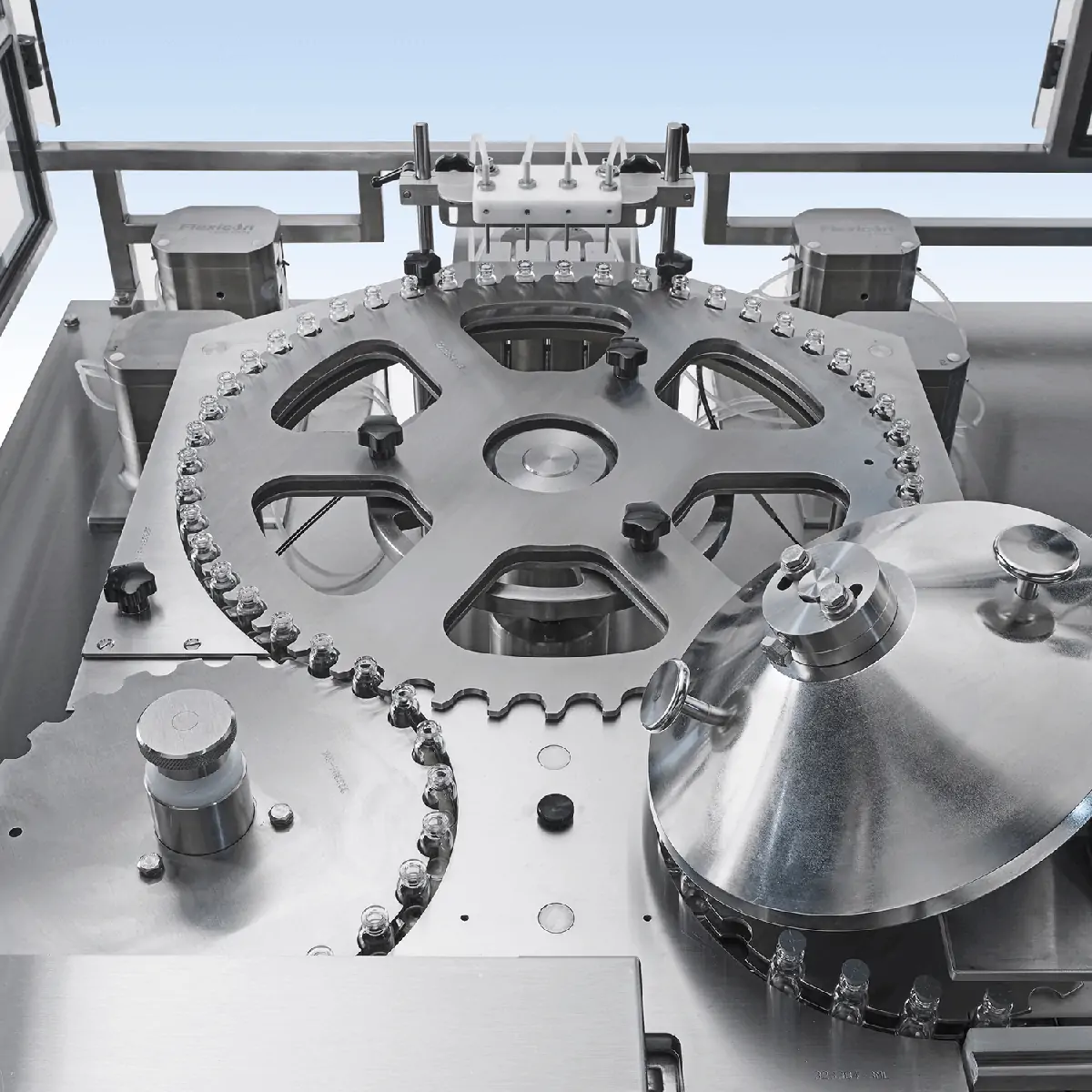

Ampoule Filling Machines

FPS - Ampoule Filling and Sealing

- Ideal for filling and sealing ampoules with speeds from 15-120 ampoules per minute and a fill accuracy of +/- .5%.

- The FPS is designed with a sealed top cover plate to ensure the internal drive mechanism remains free of extraneous matter.

HS1 - Ampoule Sealer

- The HS1 ampoule hand sealer will tip or pull seal your ampoules, then flame polish the seal.

- This machine is ideal for lab or small scale production facilities.

Syringe Filling Machines

F329HE - Syringe Filler

- High performance filler for moderate production output in a batch filling operation.

- Provides production rates of one tub of Hypak syringes in 35 seconds – depending on format, fill volume and liquid flow characteristics.

MVP - Stoppering System

- Reliable, semi-automatic, batch insertion of stoppers, plungers or plugs into filled containers.

- Perfect companion to the F329 Series liquid filling machines.

MonoBlock Filling Machines

FSV50 - Filling & Stoppering Machine

- This machine will fill liquids, then stopper the containers using full or partial stopper insertion.

- Speeds of up to 50 containers per minute with a fill accuracy of +/- .5% can be achieved with the FSV50.

RFPC - Filling, Plugging and Capping

- The RFPC series can handle various container shapes and sizes and a wide range of products from aqueous to heavy oils, suspensions and creams.

- This machine can be equipped with 1-4 nozzles and is capable of filling up to 200 vials per minute with a fill accuracy of +/- .5%.

FPS - Ampoule Filling and Sealing

- Ideal for filling and sealing ampoules with speeds from 15-120 ampoules per minute and a fill accuracy of +/- .5%.

- The FPS is designed with a sealed top cover plate to ensure the internal drive mechanism remains free of extraneous matter.

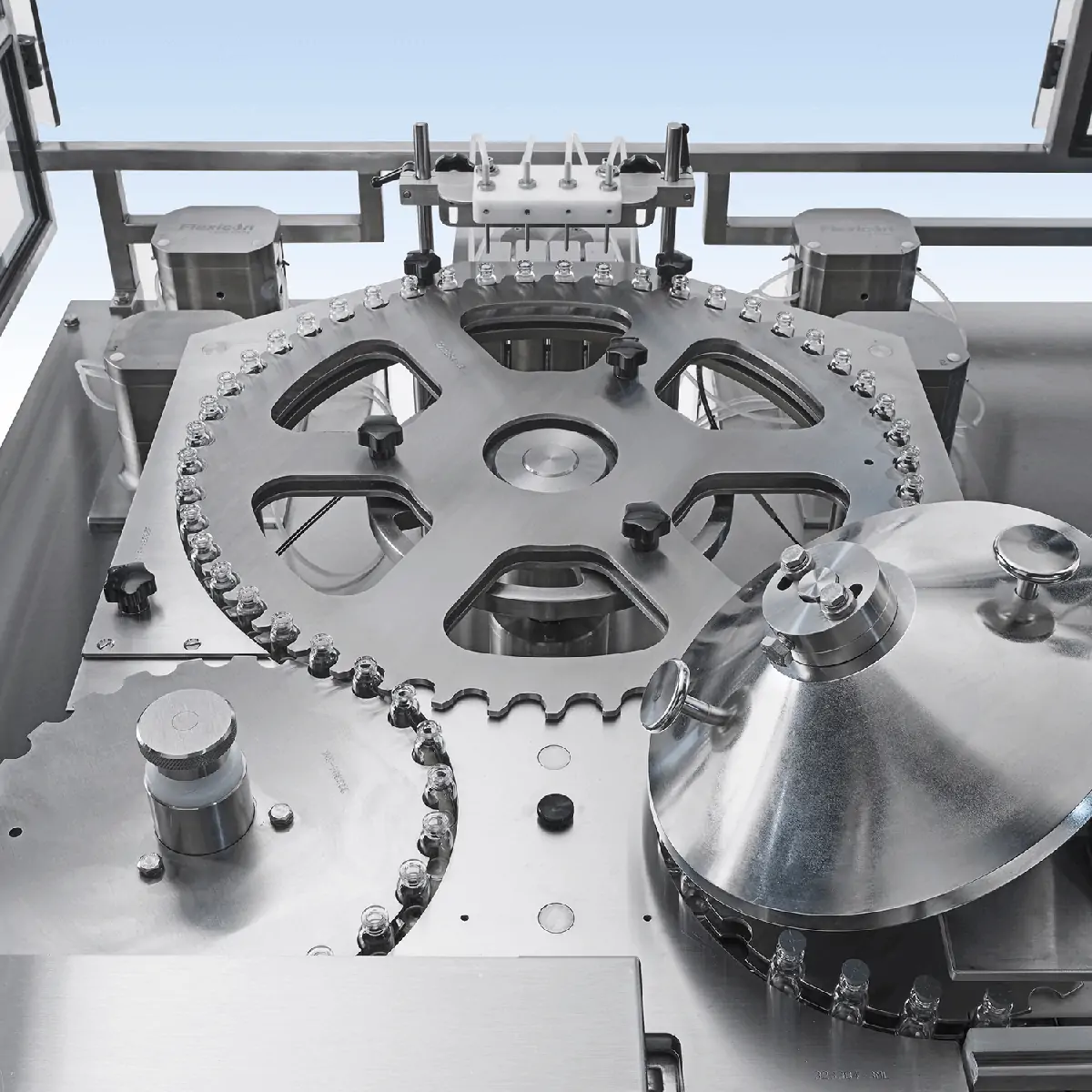

CR Series - Filling & Stoppering Machine

- The CR Series provides continuous-motion filling and stoppering.

- Offering production speeds up to 200 and 400 containers per minute, this machine performs with outstanding fill accuracy of +/- .5% or better, with either full or partial insertion of stoppers.

VR840S - Filling & Stoppering Machine

- A fill accuracy of better than +/- .5% with speeds up to 120 bpm.

- The diving nozzle system, which uses bottom-up fill on a range of 0-6”, facilitates a quick changeover.

Capping and Closing Machines

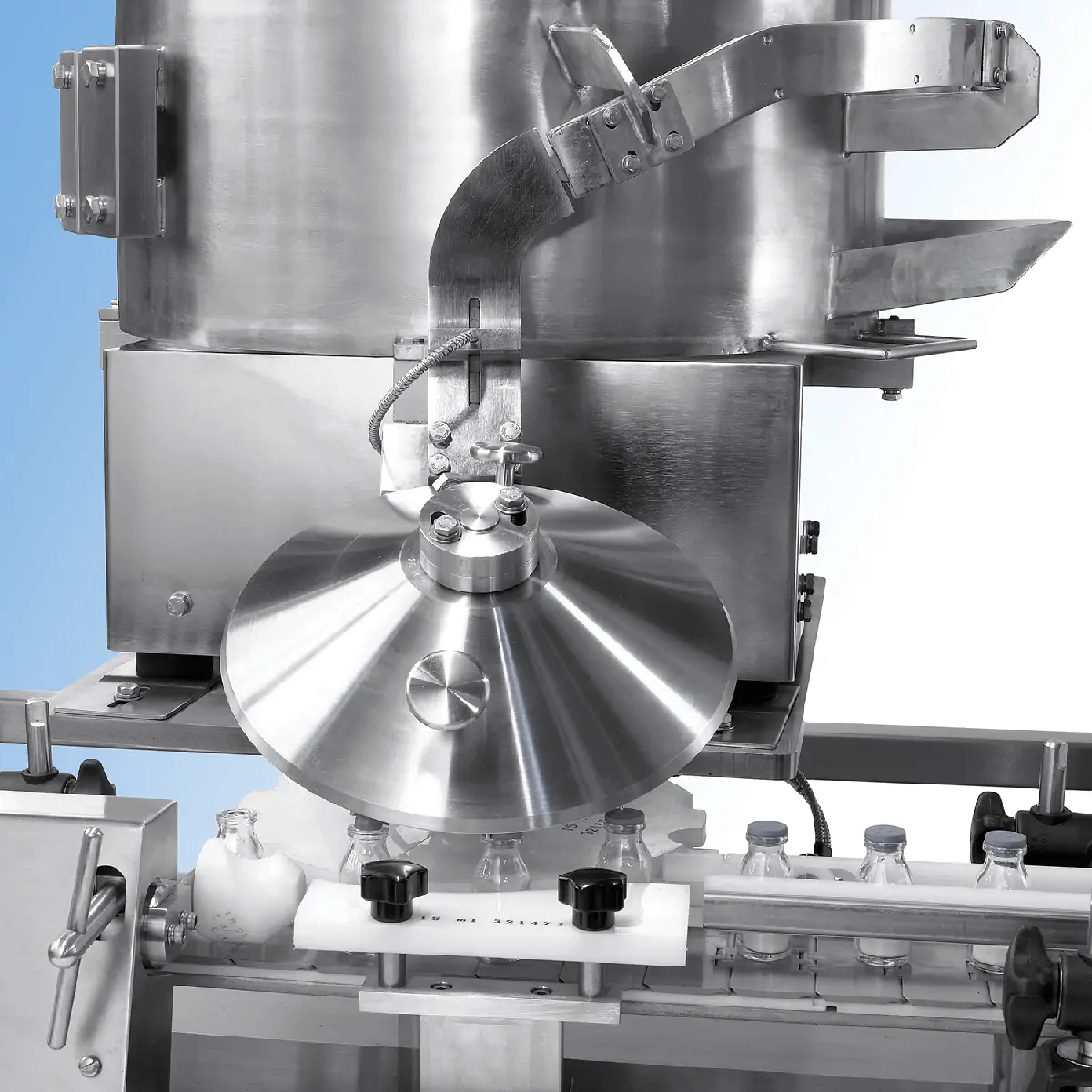

CM Series - Rotary Crimping Machine

- This high speed rotary crimping machine handles stoppered containers with absolute control while it automatically caps and crimp seals aluminum closures at speeds of up to 200 or 400 containers a minute.

MVP - Stoppering System

- Reliable, semi-automatic, batch insertion of stoppers, plungers or plugs into filled containers.

- Perfect companion to the F329 Series liquid filling machines.

RS Series - Stoppering Machine

- The RS Series can be furnished with a special stoppering head to handle dispenser plugs, such as those used to restrict the flow of topical solutions.

- Ideally suited for cleanroom environments, the RS Series offers full insertion and full or partial insertion, depending on the model of stoppers at speeds up to 400 containers/minute.

SC50T - Tabletop Screw Cap/Crimping Machine

- Provides uniform tightening of container caps up to 95mm in diameter and provides gentle cap handling.

- Ideal for lab use with speeds up to 50 containers per minute.

Washing and Sterilizing Machines

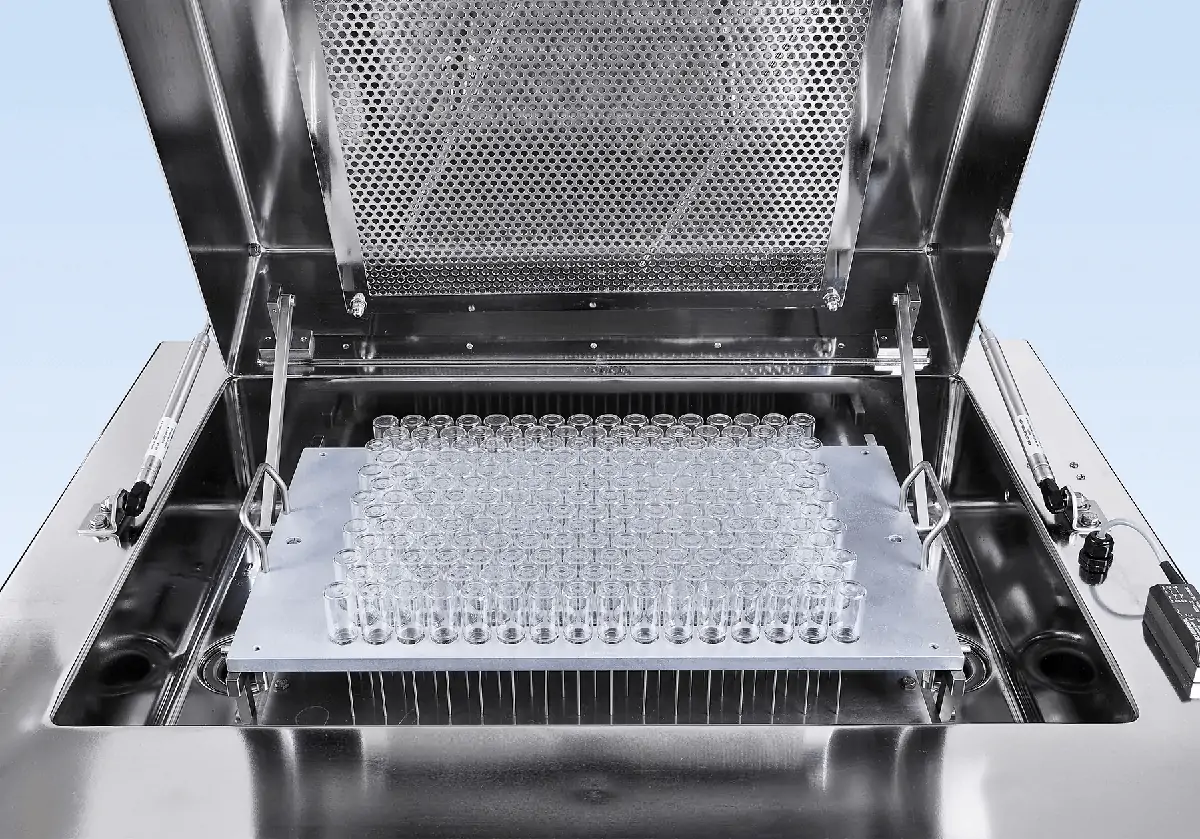

AW - Automatic Vial Cleaning System

- The AW Series features air-vacuum pre-cleaning, full penetration of nozzles without vial interior contact, flexible wash sequence and low WFI consumption.

- This series can handle vial sizes ranging from 1ml – 500ml with speeds up to 30,000 vials per hour.

GW - Vial Washer

- Handles various media including sterile air, water and steam.

- This washer can handle vial and ampule sizes from 1ml to 500ml with speeds up to 10,000 containers per hour.

- Changeover is quick and easy and the GW Series is exceptionally low maintenance.

SW - Stopper Washer

- The stopper washing machine, Model SW, offers accurate repeatable washing cycles and innovative design features – like user-programmable wash cycles with coded access, sanitary supply plumbing, stainless steel exterior, and lots more!

- This washer can handle up to 23,000 13mm stoppers per hour or 6,200 20mm stoppers per hour.

Accessories

Checkweighing

- This state of art system uses Magnetic Force Restoration type Weighing Technology that provides high speed/ high precision performance and can handle up to 200 containers per minute.

Inspection Systems

- Compact standalone units that are ideal for use in areas with space limitations.

- Speeds of more than 600 containers per minute, you can inspect 100% of your products and ensure that your shipments are defect free.

- Eliminate inspection personnel, fatigue factor, data collecting, and recording.

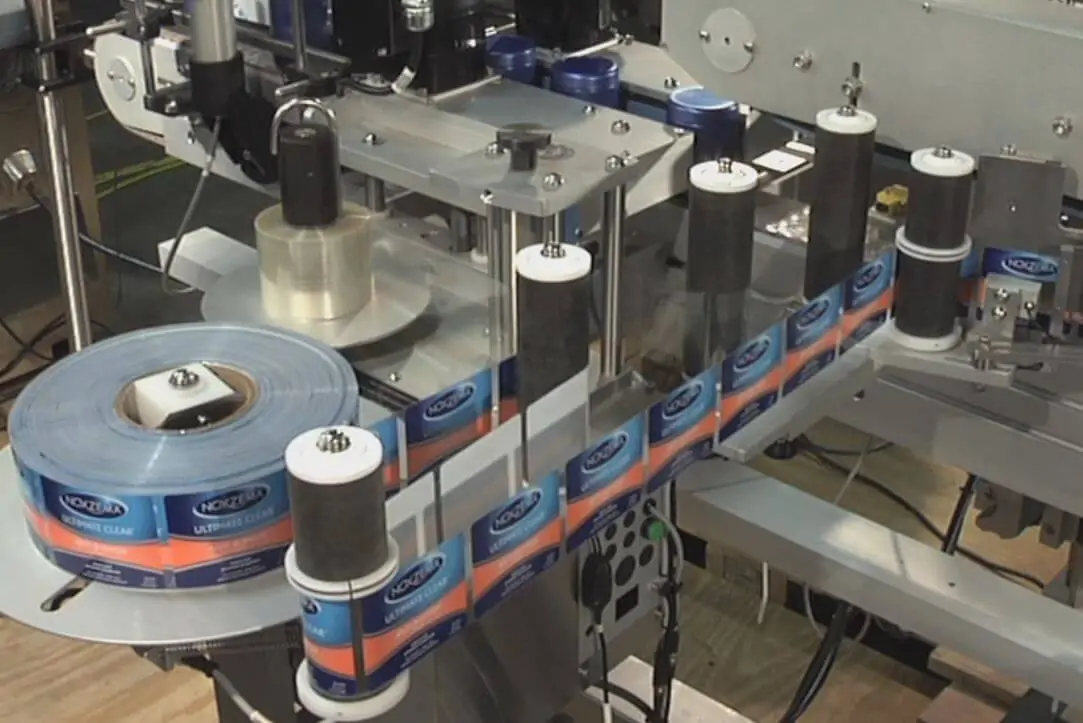

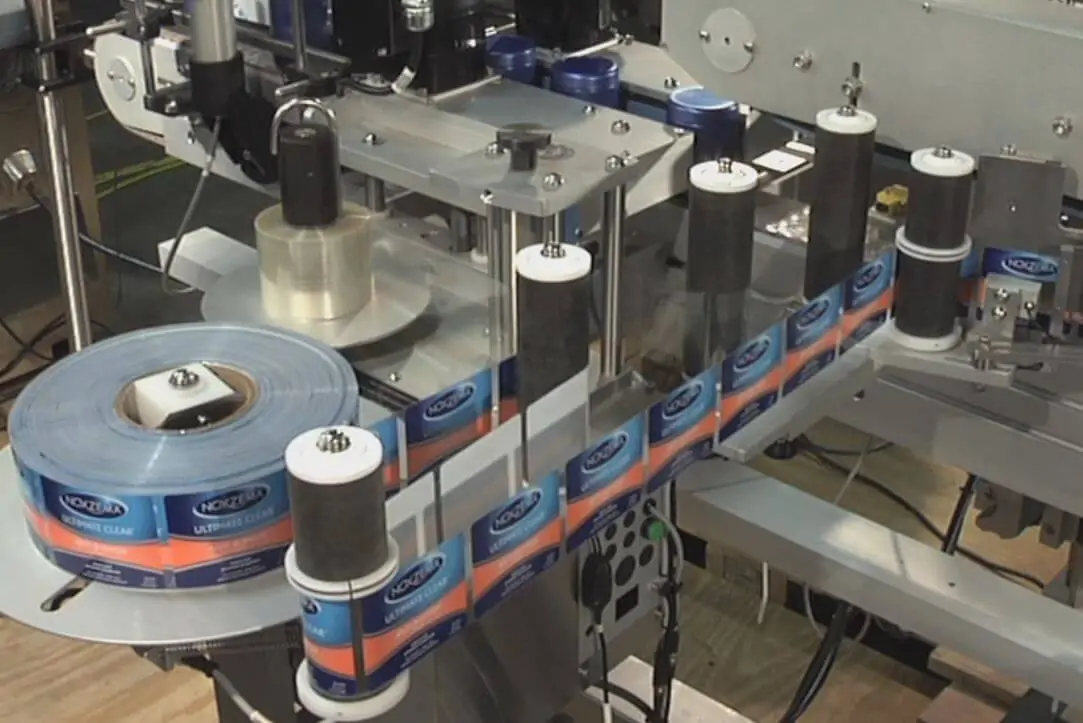

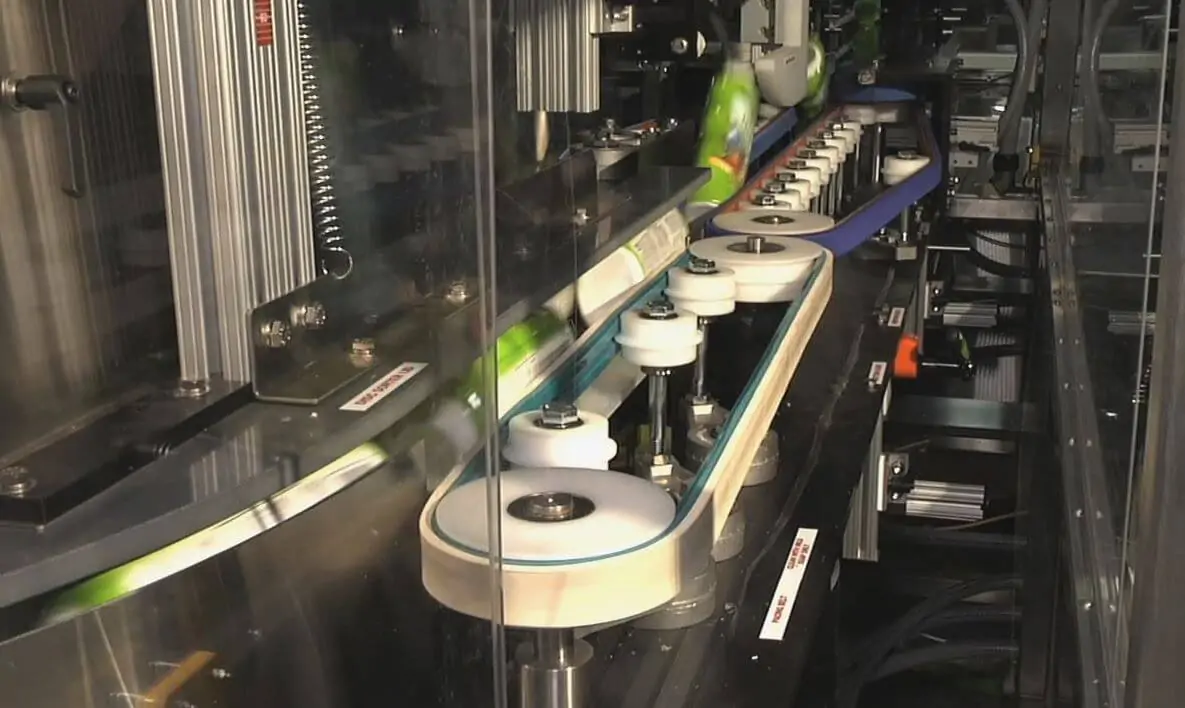

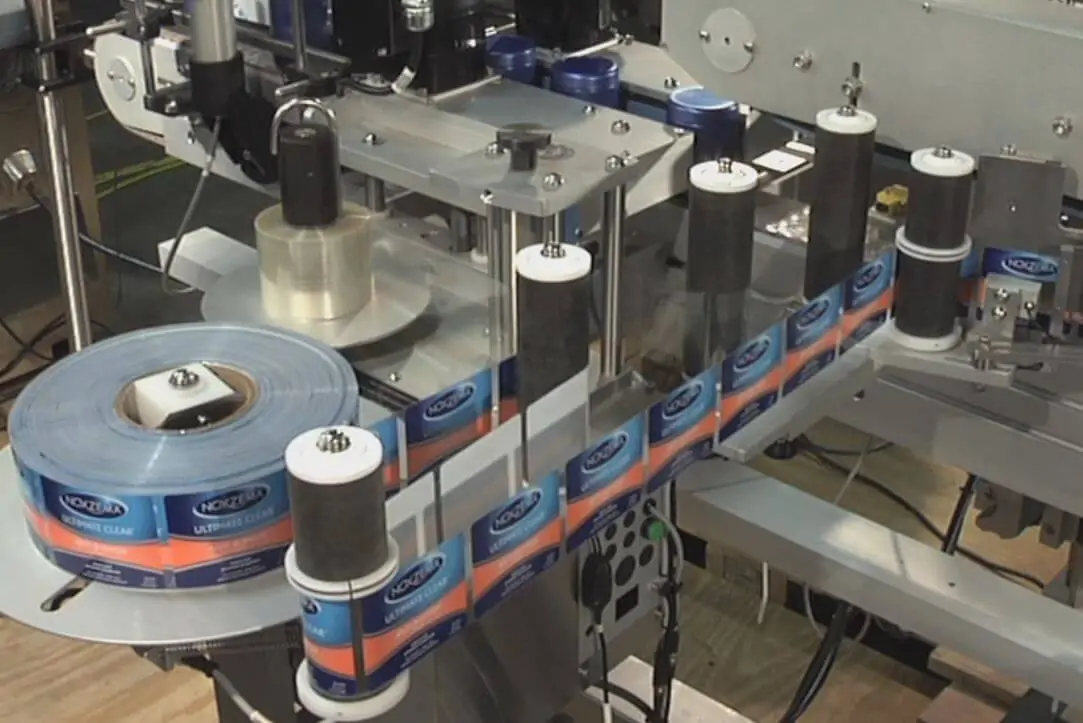

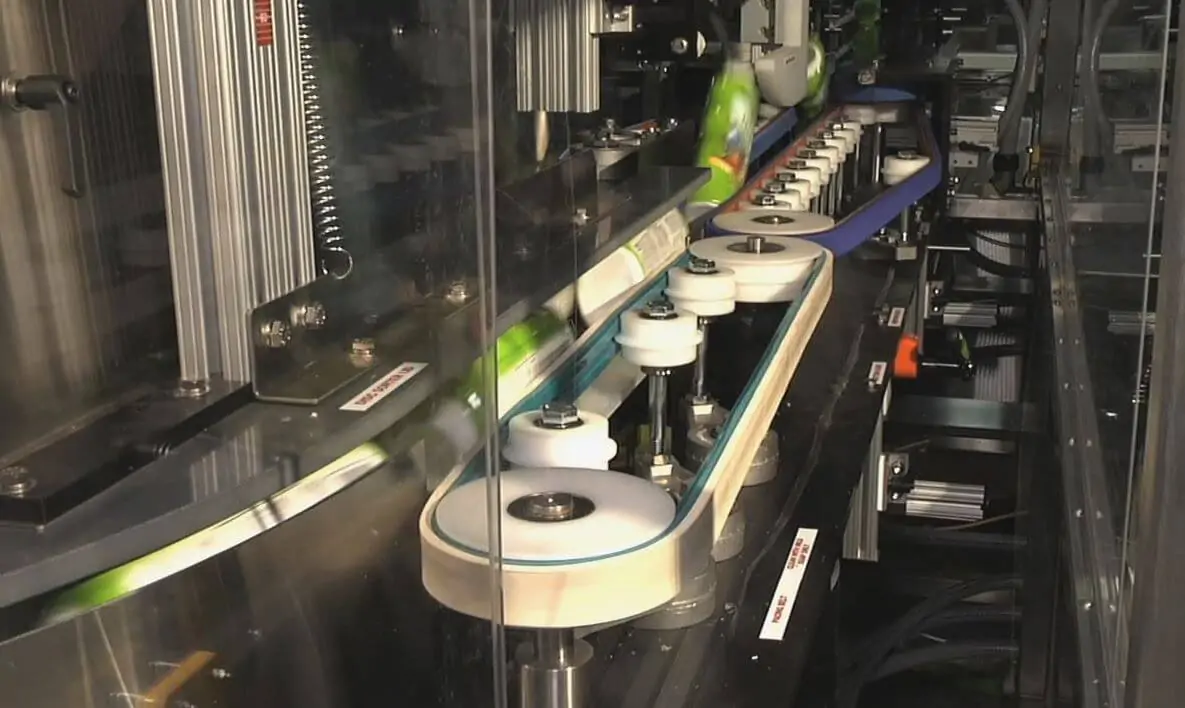

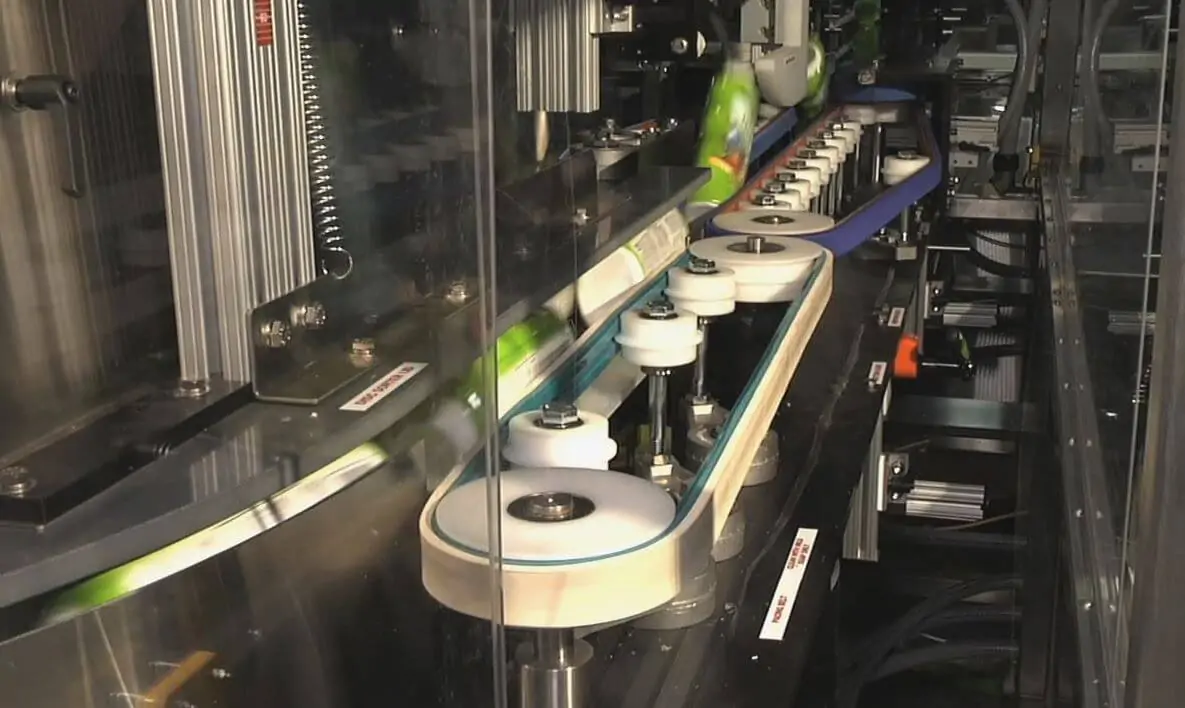

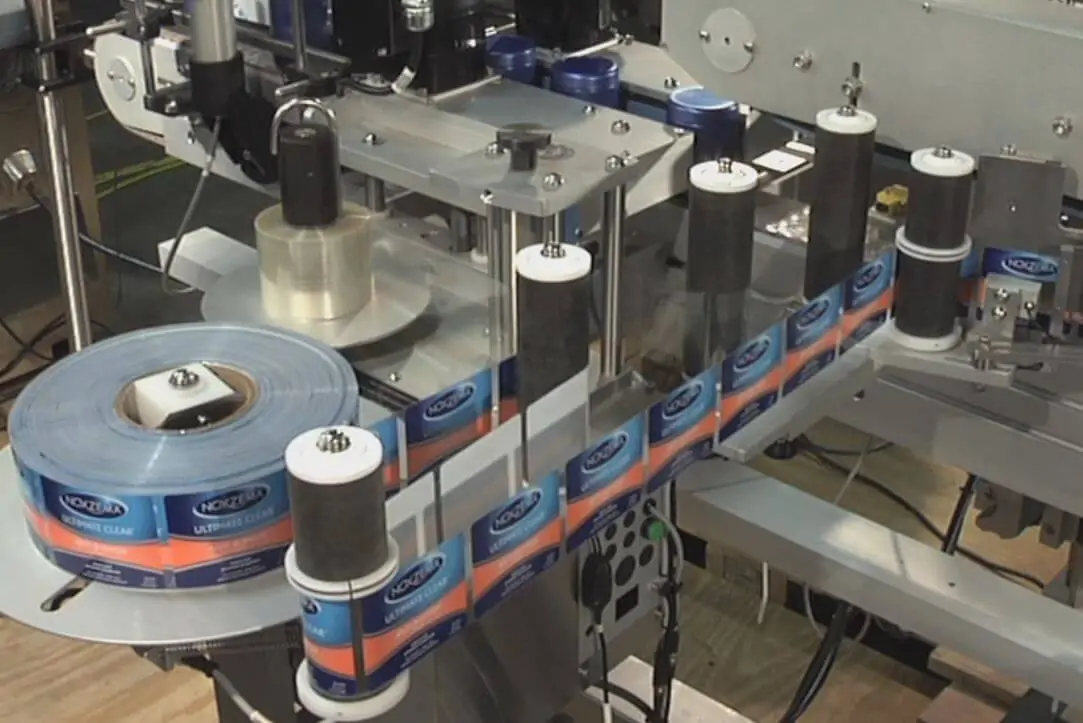

Labeling

- A variety of customized and integrated labeling systems to your operations.

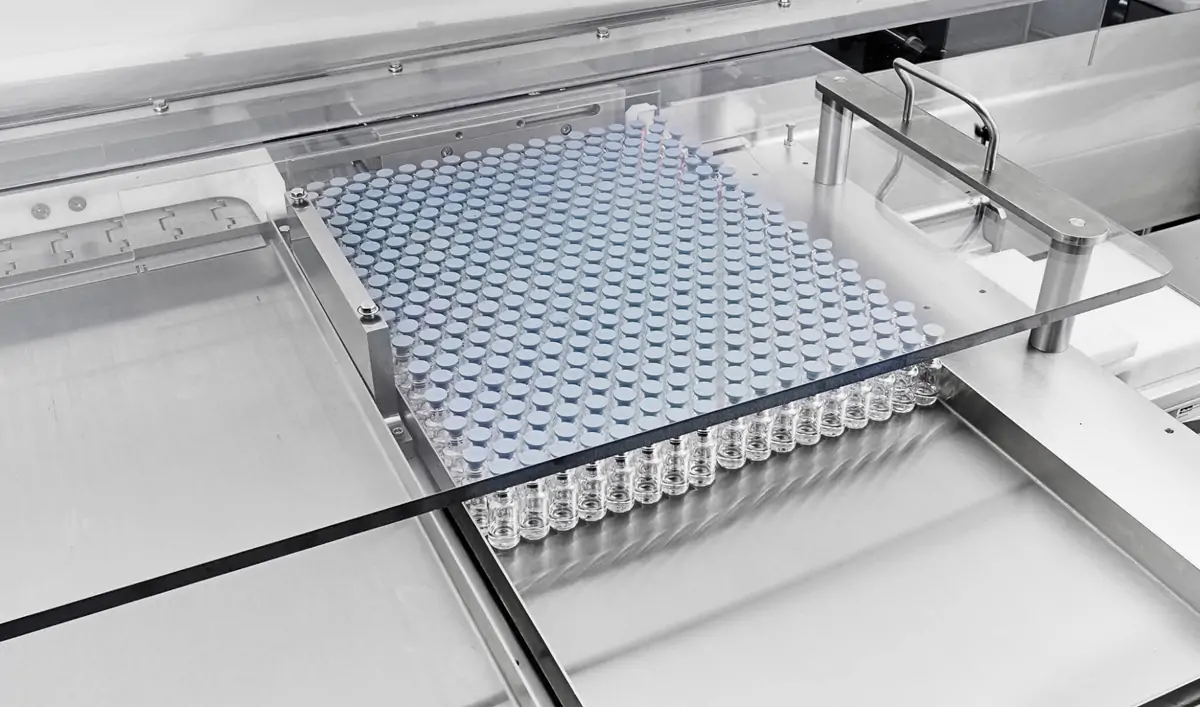

Tray Loading

- Our trey loaders incorporate an infeed conveyor that directs containers into a dual-tray staging area where rows of vials are placed into three-sided trays.

- These machines can handle1/2” to 3 ½” containers at up to 20 rows per minute.

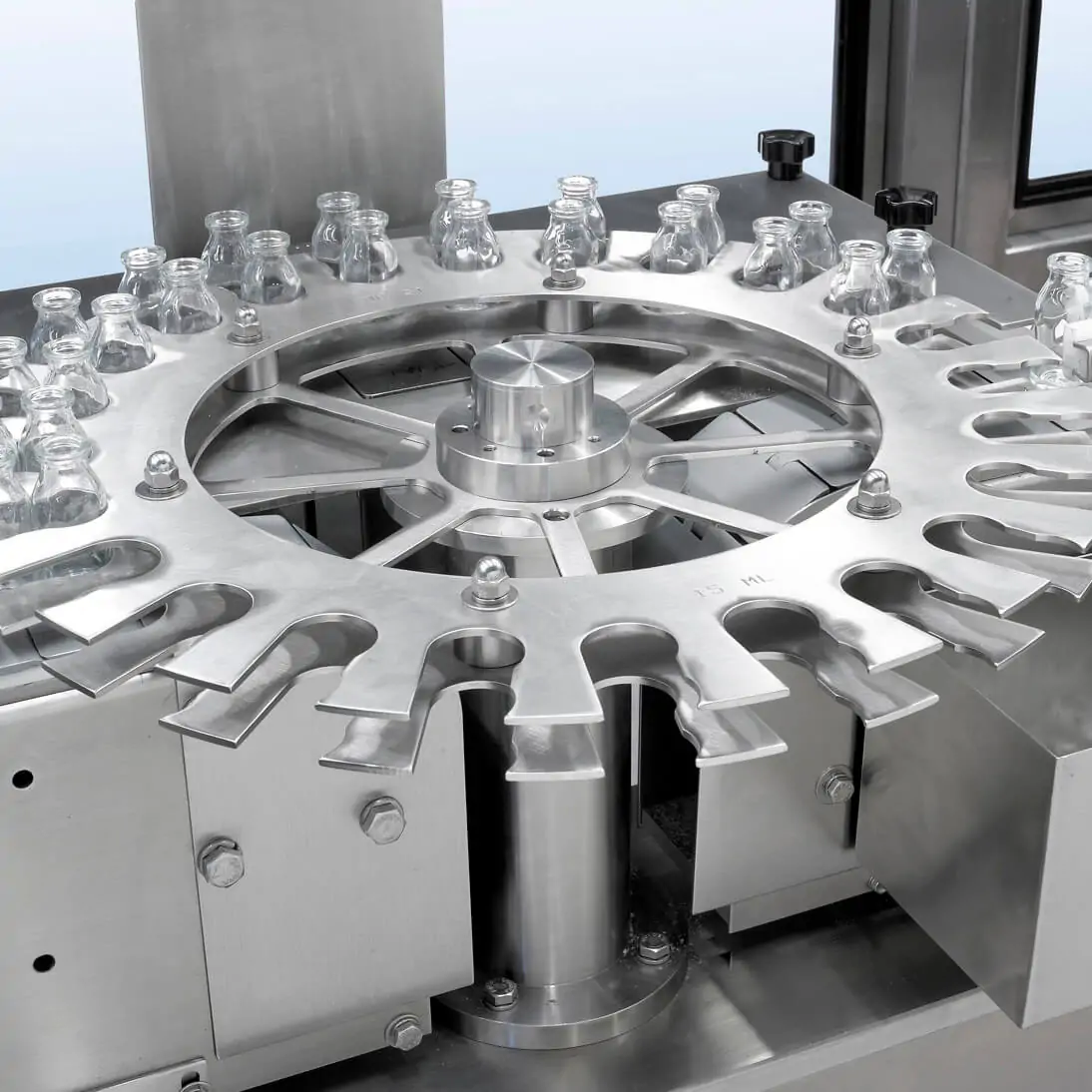

Unscrambling/Accumulating

- The accumulating and unscrambling tables are available in 5 sizes.

- Unscramblers are positioned at the start of the production line for inflow to containers.

- Accumulators can be located at any point on the production line where either smooth transfer between machines and/or accumulation is required.

Industrial Products

Liquid Filling Machines

RPF - Rotary Piston Filler

- They accommodate a wide range of containers and products of most viscosities at high production speeds of 600+ per minute.

- The overhead driven pistons feature fine fill piston adjustment, achieving ±0.5% fill accuracy.

- Cylinders and pistons are easily removed for cleaning or changeover to other sizes.

RFL - Rotary Fill-To-Level

- A fully automatic machine that fills a variety of liquids with speeds up to 900 containers per minute with fill volumes ranging from .5 oz to 1 gallon and a fill accuracy of +/- 1/16 inch.

- All RFL fillers feature a top gear drive shielded to assure cleanliness and include centrally clustered manual lubrication systems for ease of maintenance.

Versa-Fil

- Well suited to filling heavy viscosity food products like mayonnaise, peanut butter and relish as well as a variety of lighter products.

- It can be equipped with 4 to 24 spouts, with a maximum container diameter from 3.14″ to 8.50.”

- This machine can be designed to handle fill volumes as small as 5 cc up to imperial gallons, with a fill accuracy of +/- .5%.

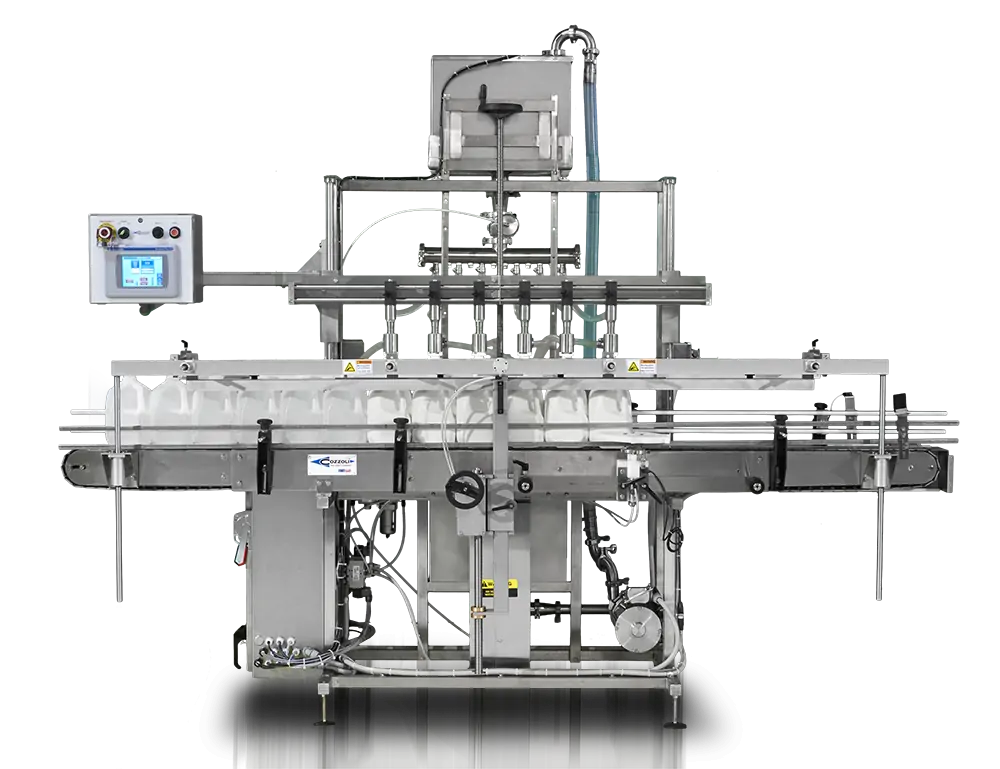

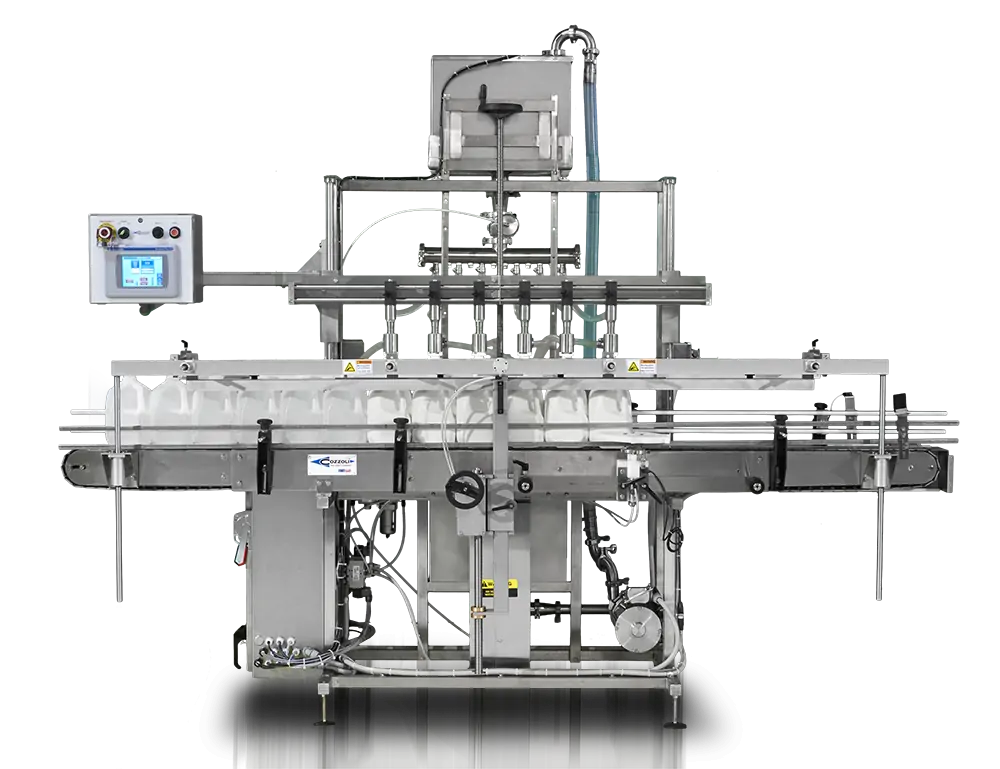

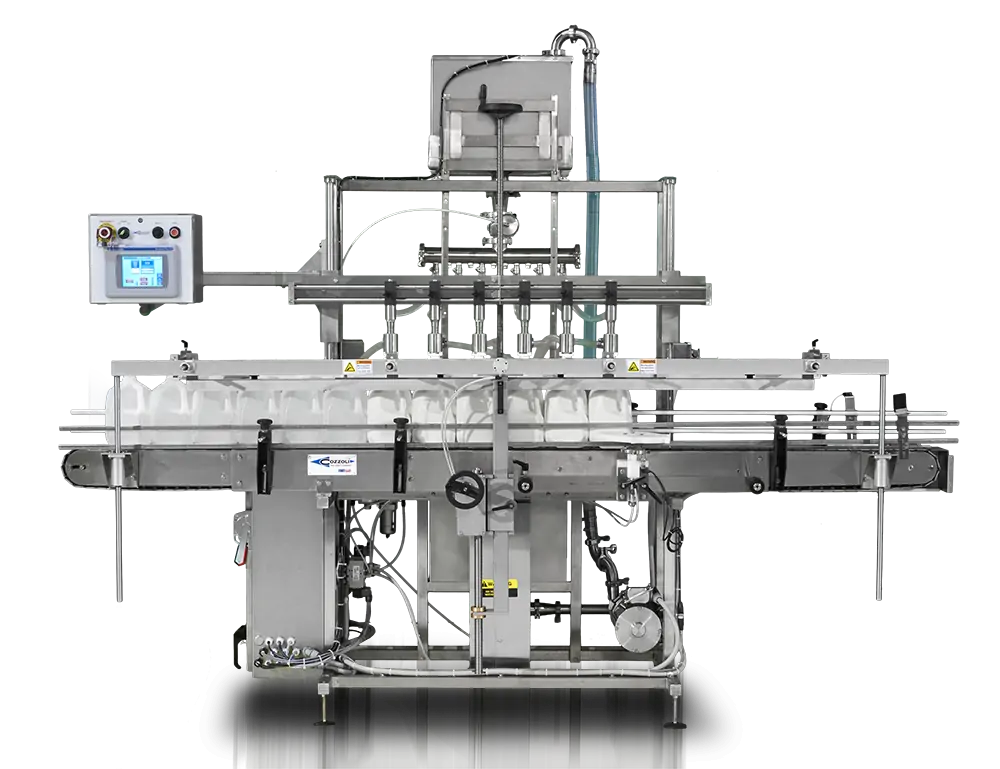

IPF - Inline Piston Filler

- It will fill product volumes from 0.37 to 157 ounces with a single stroke (depending on cylinder and piston sizing) into metal, plastic, glass or rigid paper containers.

- Larger fills are attainable with multiple strokes into the same container.

- With proper nozzle and cylinder sizing, this machine guarantees accuracies of +\- 1/2 of 1% of the fill volume.

IFL - Inline Fill-To-Level

- It fills a diverse range of liquid products in a variety of container shapes and sizes, and it can be equipped with 2-12 nozzles.

- Models range from semi to fully automatic with speeds of 14-46 containers per minute and a fill accuracy of +/- 1/16 inch.

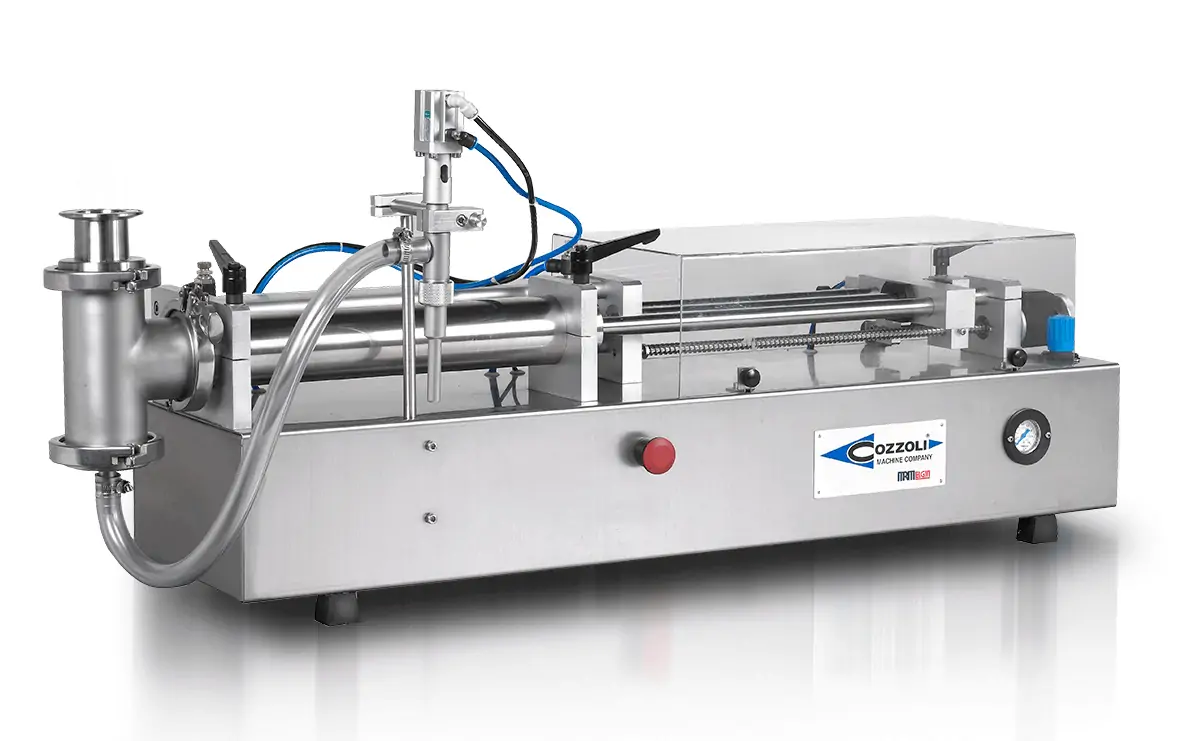

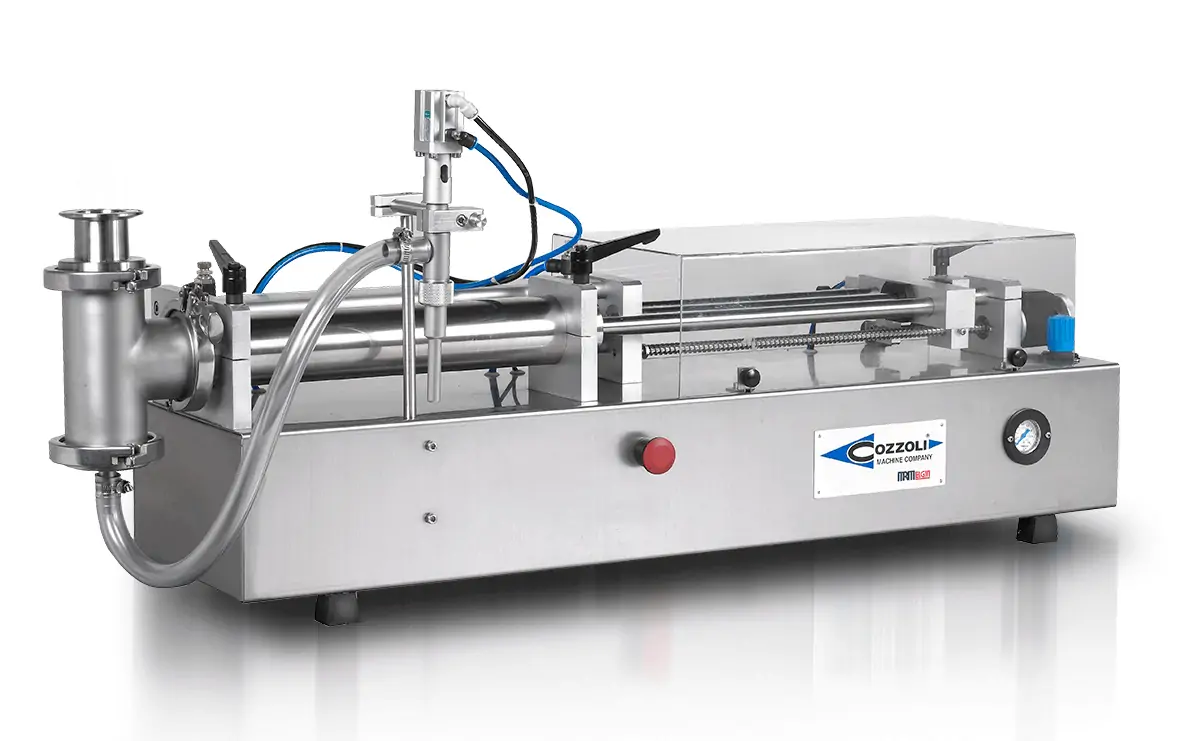

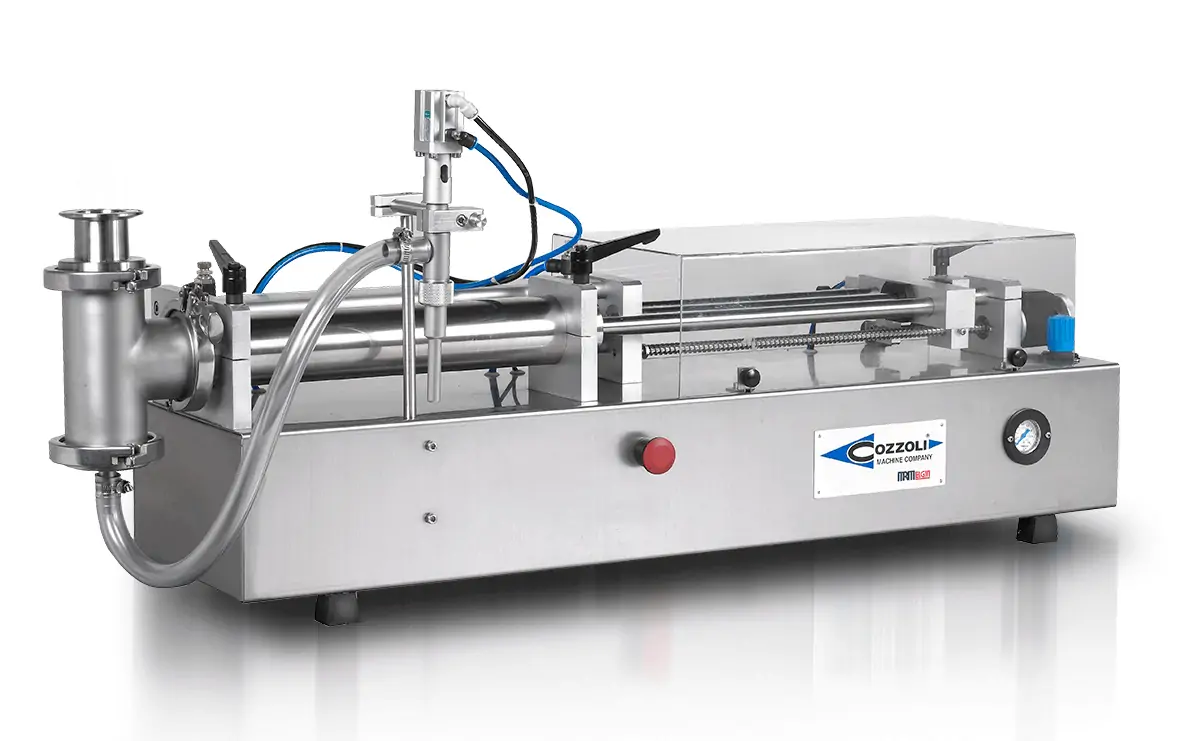

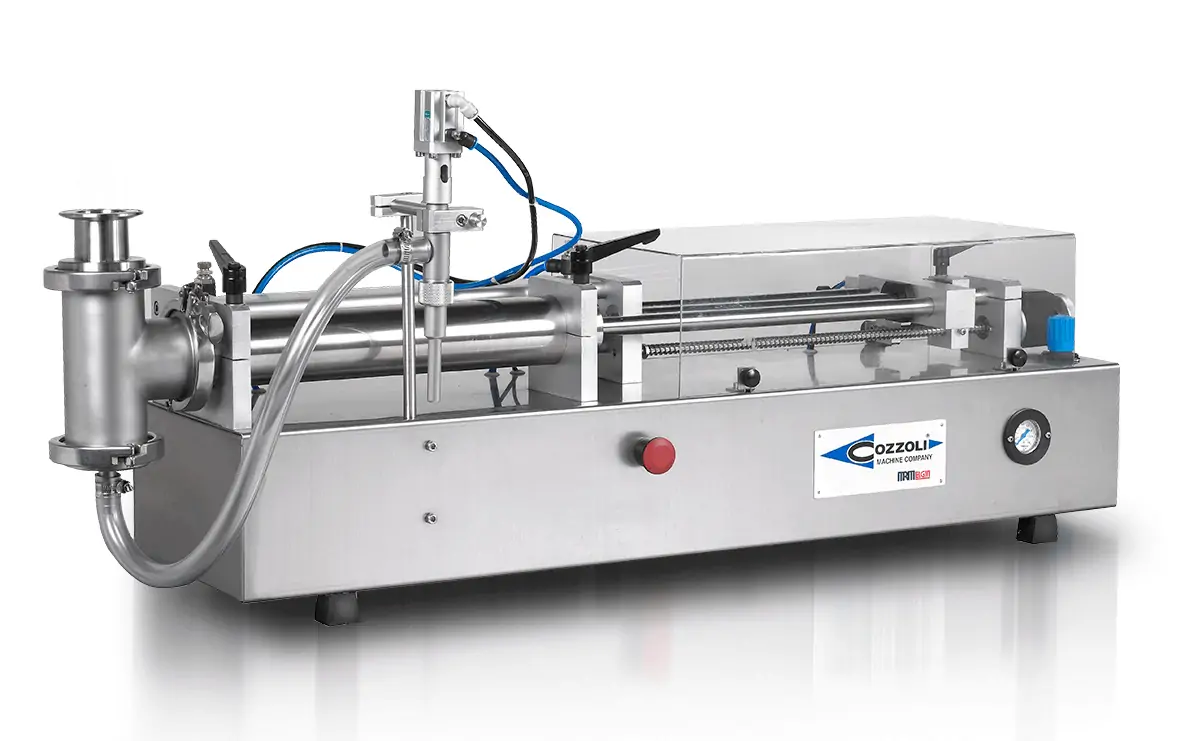

BMSV - Bench Model Piston Filler

- Designed specifically to provide accurate economical filling of viscous products for lab work and small scale filling operations.

- Ideal for filling food sauces, paints, syrups, honey, caulks, etc.

- The unit features fully pneumatic operation and provides accuracy of up to +/- .05%, by volume dependent on products viscosity and flow characteristics.

Capping Machines

Versa Cap - Friction Disc Capper

- A straight-through friction disc capper designed to handle a variety of cap sizes, ranging from 13mm to 110mm, with little or no changeover time required.

- It is easy to run, easy to adjust and uses a minimum of components to provide consistently high quality and trouble-free capping.

Accessories

Labeling

- A variety of customized and integrated labeling systems to your operations.

Unscrambling

- Designed and manufactured on a single frame with fixed change parts to ensure quick and easy “tool-less” changeovers.

- They utilize a proven “starwheel” orientation system to deliver consistent and accurate bottle discharge onto conveyors and ramps or directly into pocket wheels, timing screws and pucks.

- Thanks to the modular design, each unscrambler can be easily configured and upgraded to ensure the right end solution.

Food & Beverage Products

Liquid Filling Machines

RPF - Rotary Piston Filler

- They accommodate a wide range of containers and products of most viscosities at high production speeds of 600+ per minute.

- The overhead driven pistons feature fine fill piston adjustment, achieving ±0.5% fill accuracy.

- Cylinders and pistons are easily removed for cleaning or changeover to other sizes.

RFL - Rotary Fill-To-Level

- A fully automatic machine that fills a variety of liquids with speeds up to 900 containers per minute with fill volumes ranging from .5 oz to 1 gallon and a fill accuracy of +/- 1/16 inch.

- All RFL fillers feature a top gear drive shielded to assure cleanliness and include centrally clustered manual lubrication systems for ease of maintenance.

Versa-Fil

- Well suited to filling heavy viscosity food products like mayonnaise, peanut butter and relish as well as a variety of lighter products.

- It can be equipped with 4 to 24 spouts, with a maximum container diameter from 3.14″ to 8.50.”

- This machine can be designed to handle fill volumes as small as 5 cc up to imperial gallons, with a fill accuracy of +/- .5%.

IPF - Inline Piston Filler

- It will fill product volumes from 0.37 to 157 ounces with a single stroke (depending on cylinder and piston sizing) into metal, plastic, glass or rigid paper containers.

- Larger fills are attainable with multiple strokes into the same container.

- With proper nozzle and cylinder sizing, this machine guarantees accuracies of +\- 1/2 of 1% of the fill volume.

IFL - Inline Fill-To-Level

- It fills a diverse range of liquid products in a variety of container shapes and sizes, and it can be equipped with 2-12 nozzles.

- Models range from semi to fully automatic with speeds of 14-46 containers per minute and a fill accuracy of +/- 1/16 inch.

BMSV - Bench Model Piston Filler

- Designed specifically to provide accurate economical filling of viscous products for lab work and small scale filling operations.

- Ideal for filling food sauces, paints, syrups, honey, caulks, etc.

- The unit features fully pneumatic operation and provides accuracy of up to +/- .05%, by volume dependent on products viscosity and flow characteristics.

Capping Machines

Versa Cap - Friction Disc Capper

- A straight-through friction disc capper designed to handle a variety of cap sizes, ranging from 13mm to 110mm, with little or no changeover time required.

- It is easy to run, easy to adjust and uses a minimum of components to provide consistently high quality and trouble-free capping.

Accessories

Labeling

- A variety of customized and integrated labeling systems to your operations.

Unscrambling

- Designed and manufactured on a single frame with fixed change parts to ensure quick and easy “tool-less” changeovers.

- They utilize a proven “starwheel” orientation system to deliver consistent and accurate bottle discharge onto conveyors and ramps or directly into pocket wheels, timing screws and pucks.

- Thanks to the modular design, each unscrambler can be easily configured and upgraded to ensure the right end solution.

Personal Care Products

Liquid Filling Machines

RPF - Rotary Piston Filler

- They accommodate a wide range of containers and products of most viscosities at high production speeds of 600+ per minute.

- The overhead driven pistons feature fine fill piston adjustment, achieving ±0.5% fill accuracy.

- Cylinders and pistons are easily removed for cleaning or changeover to other sizes.

RM Series

- The Cozzoli simple two-piece filling syringes and valve assemblies are designed with easy cleaning in mind.

- High precision machining of our filling syringes allows each machine to achieve fill accuracy better than +/- 0.5% by volume.

RFL - Rotary Fill-To-Level

- A fully automatic machine that fills a variety of liquids with speeds up to 900 containers per minute with fill volumes ranging from .5 oz to 1 gallon and a fill accuracy of +/- 1/16 inch.

- All RFL fillers feature a top gear drive shielded to assure cleanliness and include centrally clustered manual lubrication systems for ease of maintenance.

Versa-Fil

- Well suited to filling heavy viscosity food products like mayonnaise, peanut butter and relish as well as a variety of lighter products.

- It can be equipped with 4 to 24 spouts, with a maximum container diameter from 3.14″ to 8.50.”

- This machine can be designed to handle fill volumes as small as 5 cc up to imperial gallons, with a fill accuracy of +/- .5%.

IPF - Inline Piston Filler

- It will fill product volumes from 0.37 to 157 ounces with a single stroke (depending on cylinder and piston sizing) into metal, plastic, glass or rigid paper containers.

- Larger fills are attainable with multiple strokes into the same container.

- With proper nozzle and cylinder sizing, this machine guarantees accuracies of +\- 1/2 of 1% of the fill volume.

IFL - Inline Fill-To-Level

- It fills a diverse range of liquid products in a variety of container shapes and sizes, and it can be equipped with 2-12 nozzles.

- Models range from semi to fully automatic with speeds of 14-46 containers per minute and a fill accuracy of +/- 1/16 inch.

BMSV - Bench Model Piston Filler

- Designed specifically to provide accurate economical filling of viscous products for lab work and small scale filling operations.

- Ideal for filling food sauces, paints, syrups, honey, caulks, etc.

- The unit features fully pneumatic operation and provides accuracy of up to +/- .05%, by volume dependent on products viscosity and flow characteristics.

Capping Machines

Versa Cap - Friction Disc Capper

- A straight-through friction disc capper designed to handle a variety of cap sizes, ranging from 13mm to 110mm, with little or no changeover time required.

- It is easy to run, easy to adjust and uses a minimum of components to provide consistently high quality and trouble-free capping.

Accessories

Unscrambling

- Designed and manufactured on a single frame with fixed change parts to ensure quick and easy “tool-less” changeovers.

- They utilize a proven “starwheel” orientation system to deliver consistent and accurate bottle discharge onto conveyors and ramps or directly into pocket wheels, timing screws and pucks.

- Thanks to the modular design, each unscrambler can be easily configured and upgraded to ensure the right end solution.

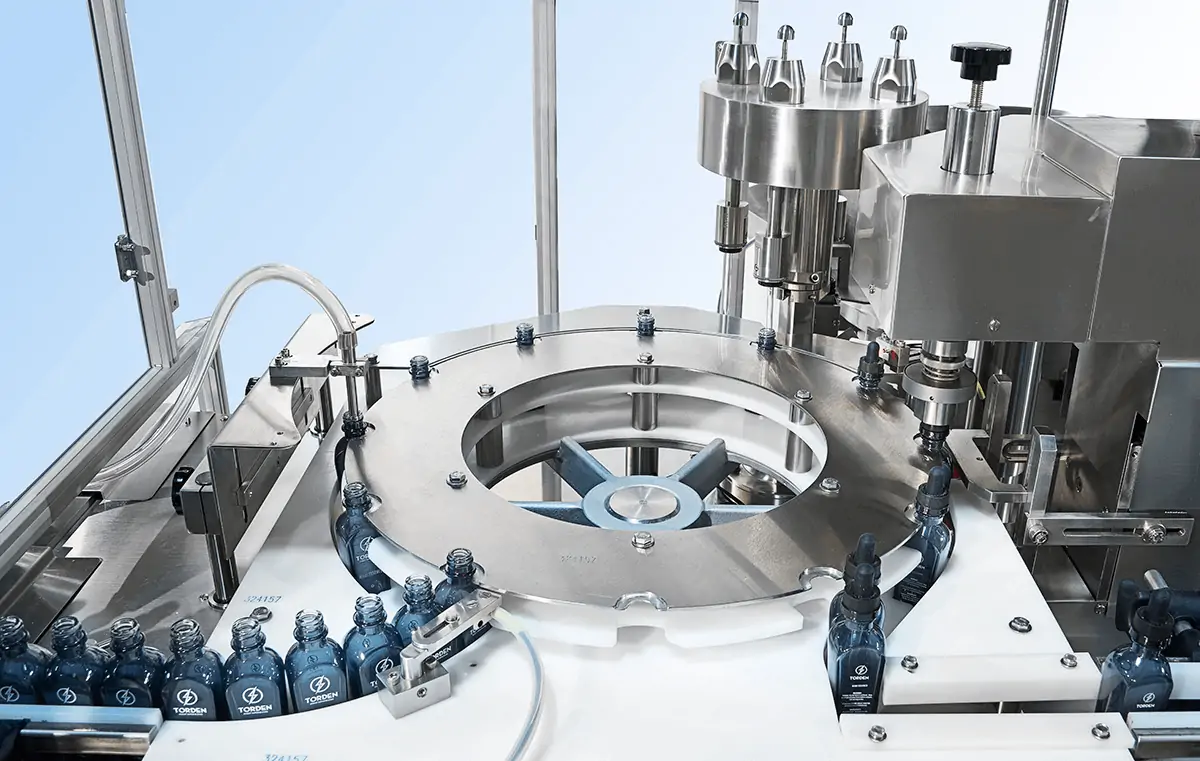

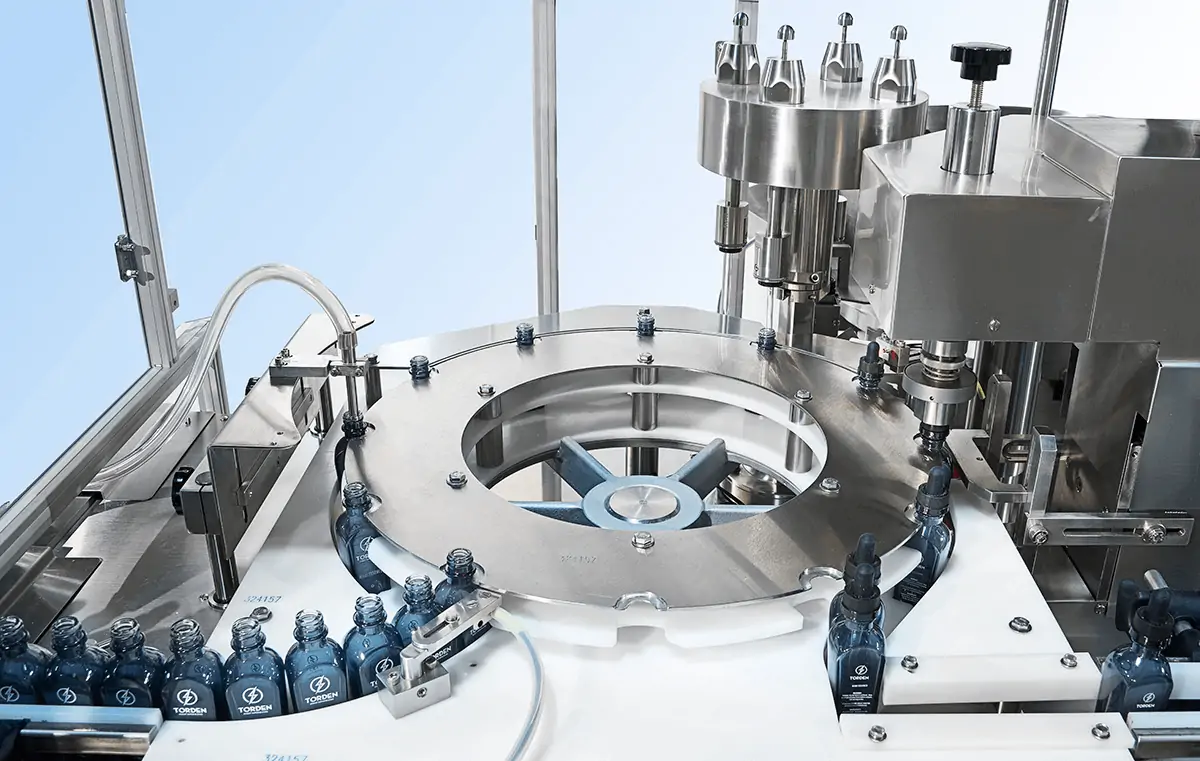

E Liquid / E Juice Products

Liquid Filling Machines

RM Series

- The Cozzoli simple two-piece filling syringes and valve assemblies are designed with easy cleaning in mind.

- High precision machining of our filling syringes allows each machine to achieve fill accuracy better than +/- 0.5% by volume.

BMSV - Bench Model Piston Filler

- Designed specifically to provide accurate economical filling of viscous products for lab work and small scale filling operations.

- Ideal for filling food sauces, paints, syrups, honey, caulks, etc.

- The unit features fully pneumatic operation and provides accuracy of up to +/- .05%, by volume dependent on products viscosity and flow characteristics.

F400X - Tabletop Filler

- Perfect for low production rates with high accuracy requirements.

- Fills aqueous solutions to light oils.

- This product is shipped fully assembled and ready to use.

- Can fill up to 50 containers a minute, depending on the operator, with accuracy of +/- .5%.

Closing and Capping Machines

SC50T - Tabletop Screw Cap/Crimping Machine

- Provides uniform tightening of container caps up to 95mm in diameter and provides gentle cap handling.

- Ideal for lab use with speeds up to 50 containers per minute.

Accessories

Labeling

- A variety of customized and integrated labeling systems to your operations.

Unscrambling/Accumulating

- The accumulating and unscrambling tables are available in 5 sizes.

- Unscramblers are positioned at the start of the production line for inflow to containers.

- Accumulators can be located at any point on the production line where either smooth transfer between machines and/or accumulation is required.