HICOF is the innovative and dynamic technology leader in the Track & Trace industry. We offer turn-key solutions combining our own serial data management software with industrial production lines for coding of packs and aggregation of serialized packaging hierarchies. For the customer this means: One solution – One supplier – One responsibility. We operate on a global base with a focus on the pharmaceutical industry.

Coding Machines

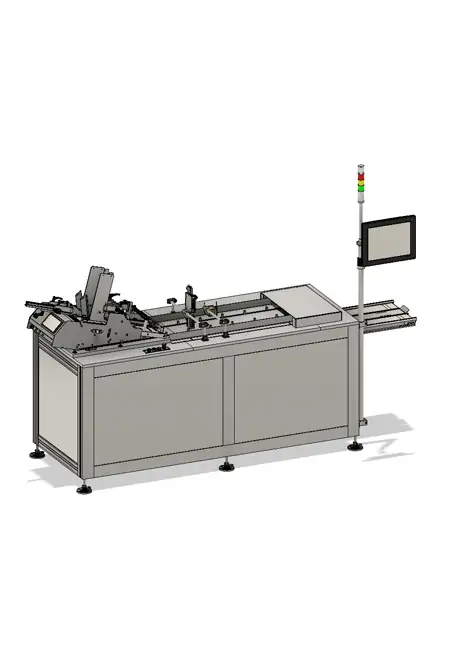

HICOF AMACODER

The HICOF AMACODER is a revolutionary coding line with tamper evident label applicators, based on an intermittent box transport mechanism. The line, made with Swiss craftsmanship is only 1.12 m long, providing high quality output and low reject rates.

AMACODER TE150

The AMACODER-TE150 is the ideal machine to integrate into automatic packaging lines. Offering economic design with fast changeover times. The AMACODER-TE150 is ideally combined with the AMAPACKER-S150 to offer seamless serialization with aggregation.

- Machine performance up to 150 pcs/min

- Machine width 1120mm

- Box Width 30-150mm

- Box Depth 55-200mm

- Box Height 15-150mm

AMACODER TE300

The AMACODER-TE300 marks the top of the line AMACODER Model which offers superior speed and product control even for critical applications.

- Machine performance up to 300 pcs/min

- Machine width 1650mm

- Box Width 30-150mm

- Box Depth 65-200mm

- Box Height 15-100mm

AMACODER TE75

The AMACODER-TE75 is the most versatile model offering highest flexibility for Box sizes ranging from 55 to 300mm. Thereby the AMACODER-TE75 is offering the shortest overall footprint of all AMACODER models. This makes the AMACODER-TE75 the ideal machine for manual packaging operations.

- Machine performance up to 80 pcs/min

- Machine width 1080mm

- Box Width 30-150mm

- Box Depth 55-300mm

- Box Height 15-150mm

AMACODER C150

The AMACODER-C150 is the ideal coding machine for packaging to integrate into automatic lines. Offering economic design with fast changeover times. The AMACODER-C150 is ideally combined with the AMAPACKER-S150 to offer seamless pharma serialization with aggregation.

- Machine performance up to 150 pcs/min

- Machine width 770mm

- Box Width 30-100mm

- Box Depth 55-200mm

- Box Height 15-150mm

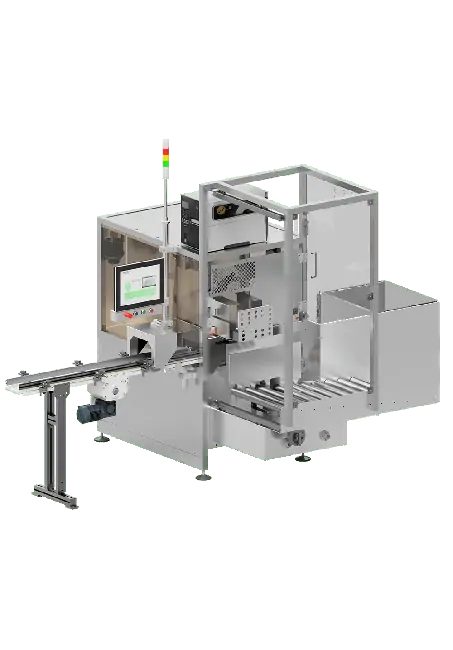

HICOF AMAPLAN

The HICOF AMAPLAN is a line of super compact flat carton serialization machines for intermittent and continuous operation. High format flexibility with short changeover times are key advantages that are fulfilled. The machine is made in Switzerland and offers high production throughput while having low reject rates.

AMAPLAN 300

The AMAPLAN-300 Flat Carton Serialization Machine is offering superior print and verification performance through it’s servo driven separator. This allows continuous operation of the marking and the verification combined with Inkjet printing and optional Pharmacode control. The innovative 90° product flow offers the shortest overall footprint of all AMAPLAN models. This makes the AMAPLAN-300 the ideal machine for central marking operations of multiple packaging lines.

- Machine performance up to 300 pcs/min

- Machine width 1550mm

- Machine depth 850mm + 1005mm Conveyor

- Machine height 1600mm

AMAPLAN L50

The AMAPLAN-L50 Flat Carton Serialization Machine is the most versatile model offering highest flexibility for Box sizes and printing technologies. The machine does transport the separated boxes with flighted conveyors to the marking and verification stations. This allows marking in standstill position with Laser and Inkjet in one machine. This makes the AMAPLAN-L50 the ideal machine for high-end marking operations.

- Machine performance up to 50 pcs/min in intermittent mode, up to 150 pcs/min in continuous mode

- Machine length 3405mm

- Machine depth 840mm

- Machine height 1865mm

AMAPLAN B50

The AMAPLAN-B50 Flat Carton Serialization Machine is the entry level solution for print and verification through full manual feeding and rejection system. This makes the AMAPLAN-B50 the ideal machine for entry level applications.

- Machine performance up to 80 pcs/min

- Machine length 2000mm

- Machine depth 800mm

- Machine height 1800mm

AMAPLAN B100

The AMAPLAN-B100 Flat Carton Serialization Machine offers mid-range print and verification performance through the friction feeder transport system and the manual rejection. This makes the AMAPLAN-B100 the ideal machine for central marking operations of multiple packaging lines.

- Machine performance up to 150 pcs/min

- Machine length 1900mm

- Machine depth 780mm

- Machine height 1800mm

AMAPLAN B150

The AMAPLAN-B150 Flat Carton Serialization Machine offers high-end print and verification performance through the friction feeder transport system and the automatic rejection. This makes the AMAPLAN-B150 the ideal machine for central marking operations of multiple packaging lines.

- Machine performance up to 250 pcs/min

- Machine length 1900mm

- Machine depth 800mm

- Machine height 1800mm

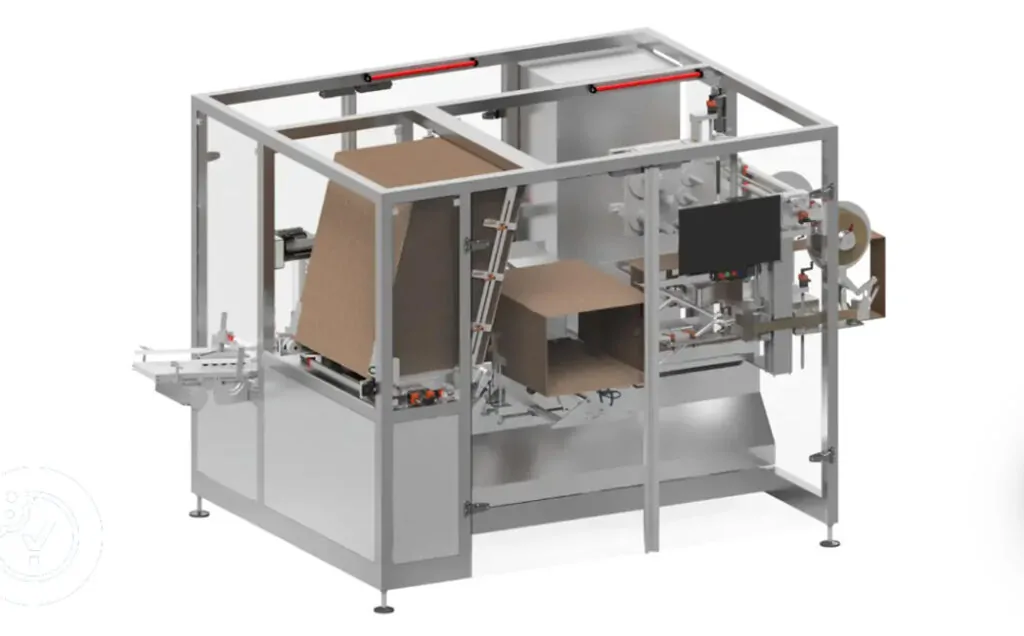

Aggregation Machines

AMAPACKER

The AMAPACKER as a semi-automatic case packer which automatically loads cartons or bundles in one or more layers into pre-formed shipping cases placed in position by an operator. One operator can pack up to 150 boxes per minutes and at the same time all aggregation processes are done by the machine in the background.

AMAPACKER S150

The AMAPACKER S150 offers within the standard the capability for aggregation. Therefore, the casepacker offers the ideal balance between packaging efficiency and short changeover times.

- Machine performance up to 150 pcs/min

- Machine width 2729 mm

- Folding Box Width 30-180mm

- Folding Box Depth 55-200mm

- Folding Box Height 15-90mm

- Shipping Case Width 30-180mm

- Shipping Case Depth 150 up to 400mm (depends on height)

- Shipping Case Height 80-350mm

AMAPACKER 150

The AMAPACKER 150 is the baseline casepacker which offers the ideal balance between packaging efficiency and short changeover times. The machine is prepared to be easily equipped with the necessary equipment for aggregation.

- Machine performance up to 150 pcs/min

- Machine width 2729 mm

- Folding Box Width 30-180mm

- Folding Box Depth 55-200mm

- Folding Box Height 15-90mm

- Shipping Case Width 30-180mm

- Shipping Case Depth 150 up to 400mm (depends on height)

- Shipping Case Height 80-350mm

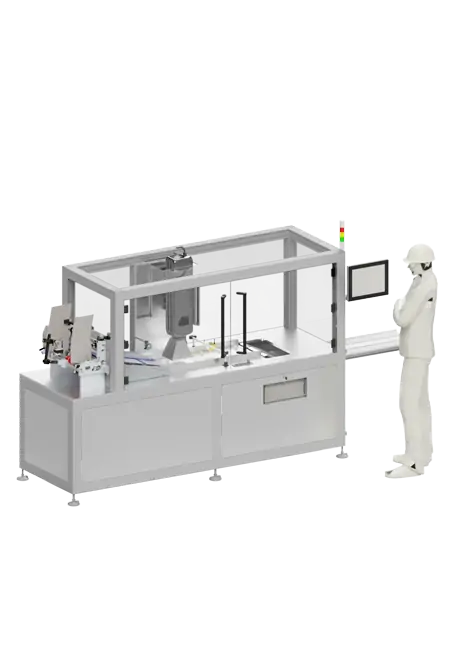

The AMAPACKER-A is a state-of-the-art, fully-automatic case packing solution that eliminates the need for human intervention. This advanced machine not only loads cartons or bundles into flat shipping cases but also automatically erects the flat cartons before filling them, autonomously managing one or more layers with precision. Gone are the days of relying on operators, as the AMAPACKER-A operates independently, following a groundbreaking ergonomic design for seamless functionality.

With a throughput rate of up to 300 boxes per minute, the AMAPACKER-A handles all aggregation processes in the background, simultaneously ensuring compliance with legal requirements. This machine represents the epitome of automation in the packaging industry, optimizing efficiency while meeting regulatory standards effortlessly.

AMAPACKER A300

The AMAPACKER A300 is the baseline casepacker which offers the ideal balance between packaging efficiency and short changeover times. The machine is prepared to be easily equipped with the necessary equipment for aggregation.

- Machine performance up to 300 pcs/min

- Machine width 2450 mm

- Machine depth 1973 mm

- Folding Box Width 30-180mm

- Folding Box Depth 55-200mm

- Folding Box Height 15-90mm

- Shipping Case Width 250-540mm

- Shipping Case Depth 180 up to 400mm

- Shipping Case Height 150-400mm

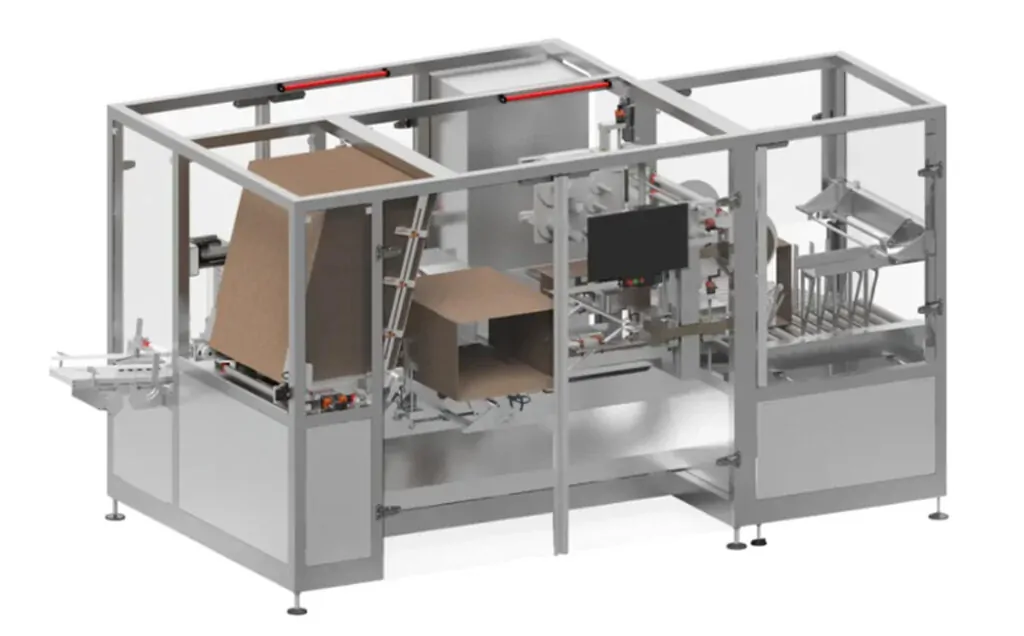

AMAPACKER A300R

The AMAPACKER A300R offers the same base features as the AMAPACKER-A300 while offering an automatic rejection station for substandard shipping cartons.

- Machine performance up to 300 pcs/min

- Machine width 3555 mm

- Machine depth 1973 mm

- Folding Box Width 30-180mm

- Folding Box Depth 55-200mm

- Folding Box Height 15-90mm

- Shipping Case Width 250-540mm

- Shipping Case Depth 180 up to 400mm

- Shipping Case Height 150-400mm

AMAJOINER

The HICOF AMAJOINER is a manual aggregation station with a high resolution overhead camera. This allows low cost aggregation of serialized products to shipping cases and pallets.

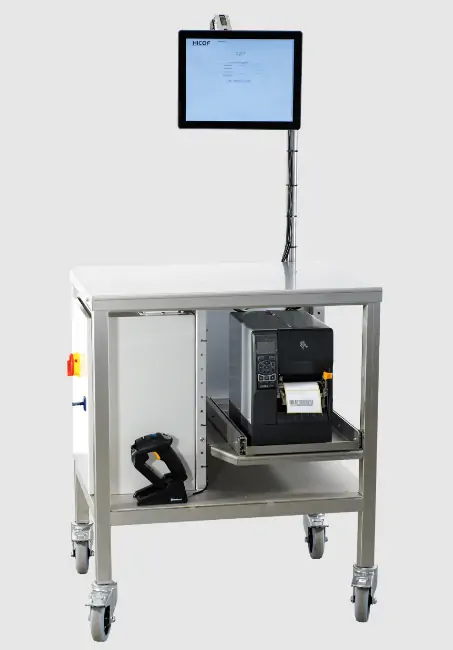

AMAJOINER 10

AMAJOINER 20

- 20Mpix Camera with Liquid lens

- Table width 1200 mm

- Table Depth 800mm

- Number of Thermotransfer printers up to 2

- Wireless datatransfer available

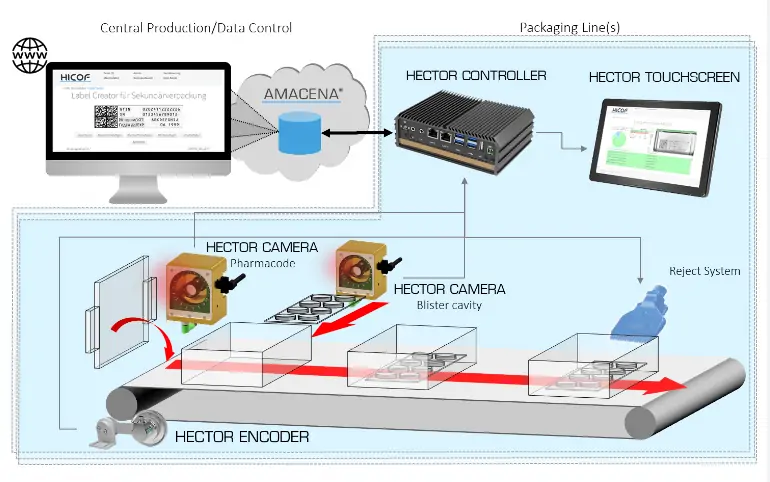

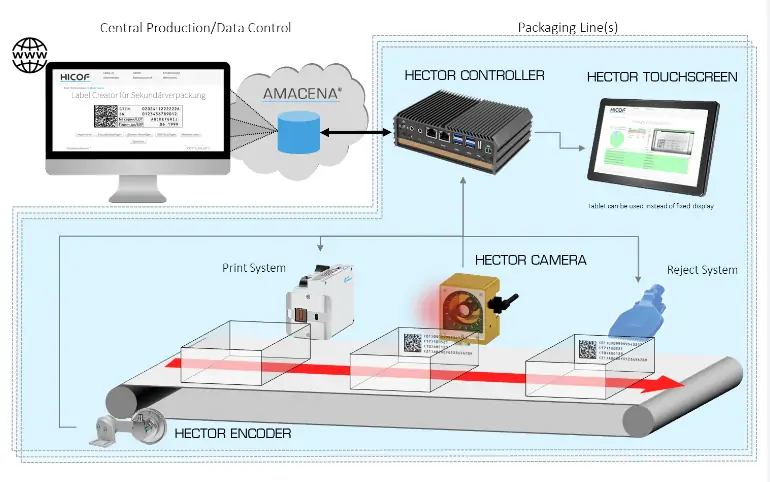

HECTOR - Serialization Hardware Kit for Items

HICOF HECTOR Serialization Hardware Kit can be integrated on any machine to manage the process of serial numbering with variable printing systems as e.g. Thermo Inkjet, Continuous Inkjet or Laser Printing. HECTOR includes a customisable kit of Hardware components which are all connected to the HECTOR Controller as central orchestrator of the machine. The Controller can be connected to the HECTOR Cameras which allows to perform print inspection according ISO15415 and OCR as well as to rejection systems. Additionally, HECTOR has an integrated register function which allows it to track the product through the machine based on encoder signals.

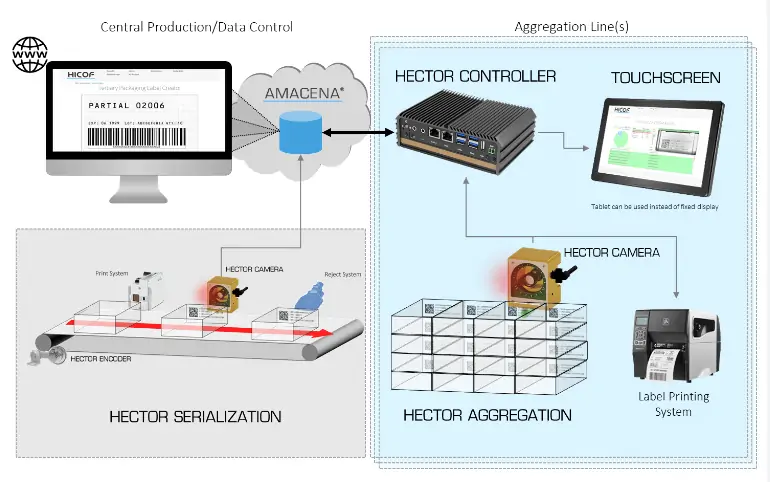

HECTOR for Aggregation

HECTOR for Quality Inspection