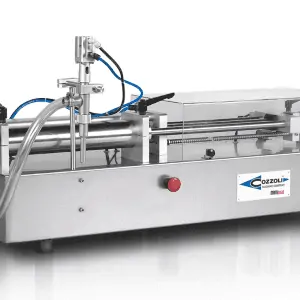

The Bio Decontamination Unit (BDU) is a high-performance chamber designed for rapid and efficient surface sterilization using hydrogen peroxide vapor (H₂O₂). Constructed from AISI 316L stainless steel with Ra <0.4 μm polish, it prevents bacterial growth and ensures easy cleaning. Featuring dual inflatable gaskets, leak monitoring, and a PID-controlled vaporizer, it guarantees airtight, repeatable decontamination in just 30 minutes. Ideal for pharmaceutical, biotech, and lab environments, the BDU also functions as a pass-through hatch with synchronized door control for enhanced workflow efficiency.

FCDV – Bio Decontamination Unit

The Bio Decontamination Unit (BDU) ensures fast, reliable surface sterilization using hydrogen peroxide vapor. Made of AISI 316L stainless steel with airtight seals, it completes decontamination in 30 minutes, ideal for labs and closed systems requiring high hygiene standards.