Digital transformation is reshaping what pharmaceutical manufacturers need from their equipment partners

The pharmaceutical manufacturing landscape is undergoing its most significant transformation in decades. Pharma 4.0—the application of Industry 4.0 principles to drug production—is fundamentally changing how manufacturers evaluate, purchase, and operate their equipment. For equipment buyers and facility managers, understanding these shifts isn’t optional; it’s essential to making smart capital investments that will serve your operation for years to come.

The global Pharma 4.0 market is projected to reach $40.3 billion by 2030, growing at nearly 20% annually. This isn’t just about adopting new technology—it’s about rethinking the entire relationship between people, processes, and machines on the production floor.

What Pharma 4.0 Actually Means for Your Equipment

At its core, Pharma 4.0 represents the convergence of automation, data analytics, artificial intelligence, and connectivity in pharmaceutical manufacturing. But what does this mean when you’re specifying a new filling line, autoclave, or labeling system?

It means equipment is no longer just a machine that performs a function. Modern pharmaceutical equipment is expected to be a data-generating asset that integrates into broader digital ecosystems, communicates with other systems, and provides actionable intelligence about its own performance and the products it handles.

The Five New Equipment Expectations

Connectivity and Integration: Equipment must communicate seamlessly with Manufacturing Execution Systems (MES), SCADA platforms, and enterprise resource planning (ERP) systems. Standalone machines that can’t share data are increasingly obsolete.

Real-Time Monitoring: Sensors for temperature, pressure, vibration, and other parameters are now standard expectations—not premium add-ons. Manufacturers want visibility into equipment performance at all times.

Predictive Capabilities: The ability to forecast maintenance needs before failures occur has moved from nice-to-have to essential. AI-driven predictive maintenance can reduce unplanned downtime by up to 50%.

Data Integrity by Design: With 21 CFR Part 11 and Annex 11 requirements, equipment must generate audit-ready data with built-in integrity controls. Retrofitting compliance is far more costly than buying it built-in.

Flexibility and Scalability: As personalized medicine and small-batch production grow, equipment must adapt quickly between products without extensive changeover time.

Predictive Maintenance: The Game Changer

Perhaps no aspect of Pharma 4.0 has more immediate impact on equipment decisions than predictive maintenance. Traditional maintenance approaches—reactive (fix it when it breaks) or preventive (fix it on a schedule)—are giving way to data-driven strategies that optimize interventions based on actual equipment condition.

Modern pharmaceutical equipment increasingly comes equipped with IoT sensors that monitor vibration, temperature, current draw, and other indicators of machine health. Machine learning algorithms analyze this data to detect subtle anomalies that indicate developing problems—often weeks before a human operator or traditional alarm would notice anything wrong.

For pharmaceutical manufacturers, the benefits extend beyond reduced downtime. Predictive maintenance helps ensure equipment operates within validated parameters, supporting both product quality and regulatory compliance. When a stability chamber or autoclave begins drifting from specification, catching it early protects batches and documentation.

What to Ask Your Equipment Supplier

When evaluating equipment with predictive maintenance capabilities, consider asking: What parameters does the equipment monitor? How is data transmitted and stored? What analytics platform processes the data? Can the system integrate with your existing CMMS (Computerized Maintenance Management System)? What has been the demonstrated reduction in unplanned downtime for existing users?

Process Analytical Technology and Real-Time Quality

The FDA has actively encouraged adoption of Process Analytical Technology (PAT) for over two decades, but Pharma 4.0 is finally making widespread implementation practical. PAT tools—spectroscopy, particle sizing, imaging systems—built directly into manufacturing equipment enable real-time quality assurance rather than relying solely on end-product testing.

Advanced sensor technologies and online analytics now enable proactive process control. For filling equipment, this might mean continuous monitoring of fill weights with automatic adjustment. For bioreactors, it could involve real-time analysis of cell culture parameters with AI-optimized feeding strategies.

Equipment buyers should understand that PAT capability adds cost—but it can dramatically reduce quality investigations, rejected batches, and time to release. The economics often favor the upfront investment, particularly for high-value biologics and complex formulations.

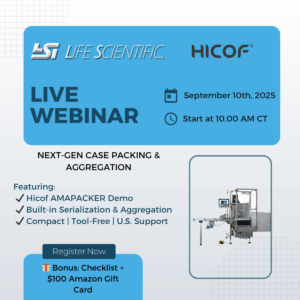

Serialization, Track and Trace, and the Data Chain

DSCSA (Drug Supply Chain Security Act) enforcement is tightening, and equipment throughout the packaging line must support serialization and aggregation requirements. But Pharma 4.0 thinking extends beyond compliance to extracting value from serialization data.

Leading manufacturers are using track-and-trace data for supply chain visibility, counterfeit prevention, and targeted recalls. Your labeling and case-packing equipment becomes part of a digital thread that follows each unit from production to patient. When evaluating serialization-capable equipment, consider not just whether it meets current requirements, but whether it can adapt as regulations evolve and as your own data strategy matures.

Containment Meets Connectivity

The growth of high-potency APIs and complex biologics has made containment a critical equipment requirement. Pharma 4.0 adds a new dimension: containment systems must now be smart systems. Isolators and restricted access barrier systems (RABS) increasingly feature environmental monitoring, automatic bio-decontamination verification, and integration with facility management systems.

The updated EU Annex 1 guidelines have accelerated this trend, emphasizing contamination control strategies that demand continuous monitoring and documentation. Equipment that was acceptable five years ago may not meet current expectations for data generation and connectivity.

Sustainability as an Equipment Criterion

Pharma 4.0 isn’t just about productivity and compliance—it increasingly encompasses sustainability. Smart equipment that optimizes energy consumption, reduces water usage, and minimizes waste is becoming a procurement priority. Digital monitoring enables precise tracking of environmental metrics, supporting corporate sustainability reporting and helping meet growing regulatory expectations around environmental impact.

When specifying new equipment, ask about energy efficiency ratings, water consumption, and options for optimized resource usage. Equipment with lower operating costs over its lifecycle often justifies higher upfront investment.

Practical Steps for Equipment Buyers

Navigating Pharma 4.0 requirements doesn’t mean replacing everything at once. Consider these practical steps:

Assess your digital maturity. Do you have MES and data infrastructure in place to take advantage of connected equipment? If not, highly connected equipment may deliver less value until your systems catch up.

Prioritize integration capability. Even if you’re not ready to fully utilize connected features today, buy equipment that can integrate into future digital ecosystems. Closed, proprietary systems limit your options.

Consider total cost of ownership. Equipment with predictive maintenance, better data integrity, and lower resource consumption may cost more upfront but deliver significant savings over a 10-15 year lifespan.

Partner with knowledgeable representatives. The complexity of Pharma 4.0 requirements means working with equipment partners who understand both the technology and your specific application becomes more valuable than ever.

The Bottom Line

Pharma 4.0 is not a distant future—it’s reshaping equipment purchasing decisions right now. The machines you buy today will need to function in an increasingly connected, data-driven, and regulated environment for the next decade or more. Understanding these evolving expectations helps ensure your capital investments remain productive and compliant throughout their operational life.

At Life Scientific, we work with manufacturers who are building these capabilities into their equipment. Whether you’re looking at filling and capping systems, sterilization equipment, stability chambers, or labeling solutions, we can help you navigate Pharma 4.0 requirements and find equipment that meets both today’s needs and tomorrow’s expectations.

Ready to discuss how Pharma 4.0 affects your equipment decisions? Contact Life Scientific at 800-829-5741 or visit life scientific, Inc. to schedule a consultation.