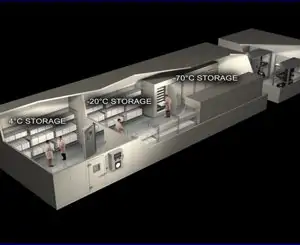

Our archival storage rooms create controlled environments for preserving irreplaceable artifacts and documents. Each archive room follows strict archival storage standards with temperature ranges from -18°C to 16°C and humidity levels maintained below 30%.

The systems feature Munters desiccant dehumidifiers, purified air handling, and advanced monitoring with touchscreen controls offering 0.1°C resolution. All components meet NARA requirements and FDA 21 CFR11 standards for data recording.

We’ve designed archive rooms for the Smithsonian, Getty Center, and Presidential Libraries. Our expertise creates specific environmental conditions for different media types—from books and films to paintings and metallic items—preventing degradation and ensuring long-term preservation of valuable collections.