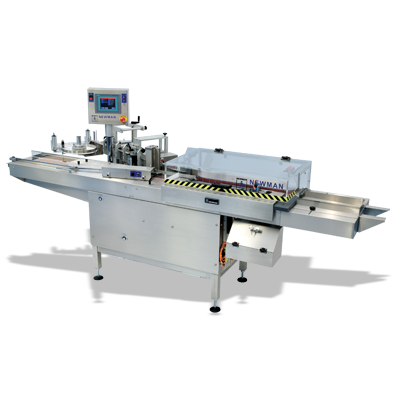

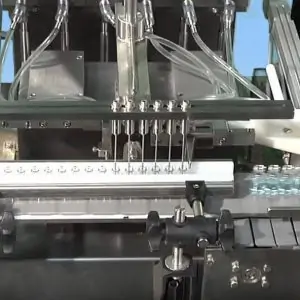

The 6VAL bottle labeling machine transforms production efficiency with speeds up to 275 containers per minute. Purpose-built for pharmaceutical and beverage bottles, ampoules, and vials, this versatile system accommodates both clear and paper self-adhesive labels with minimal changeover requirements.

The stainless steel construction ensures GMP compliance while advanced sensors guarantee precise label placement every time. Operation is intuitive via the color touchscreen interface, with comprehensive security systems ensuring error-free labeling.

Enhance functionality with optional features including bar code verification, various printing methods, and the Easisplice module for continuous operation. Boost productivity and maintain compliance with the 6VAL bottle labeling solution.

Skip to content

Skip to content