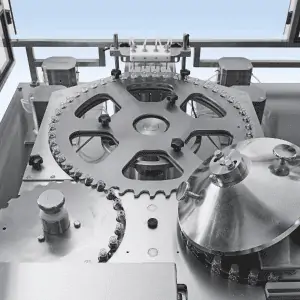

- Introducing our Tray Loader, a highly reliable stoppering system designed for seamless integration with your liquid filling processes. This semi-automatic solution is engineered to streamline the batch insertion of stoppers, plungers, or plugs into filled containers, ensuring precision and efficiency in your production line.Key Features:

- Reliable Stoppering System:

- The Tray Loader boasts a dependable stoppering mechanism, providing consistent and accurate insertion of stoppers, plungers, or plugs into filled containers. This reliability enhances the overall efficiency of your manufacturing process.

- Semi-Automatic Operation:

- Designed for ease of use, our Tray Loader offers a semi-automatic operation, striking a balance between manual control and automated efficiency. This feature allows operators to actively engage in the loading process while benefiting from the system’s automated functionalities.

- Batch Insertion Capability:

- The Tray Loader is specifically engineered for batch insertion, accommodating multiple containers at once. This capability significantly reduces downtime and enhances the throughput of your production line, making it an ideal solution for high-volume manufacturing.

- Designed for Compatibility:

- This Tray Loader is the perfect companion to our F329 Series liquid filling machines. The seamless integration between the Tray Loader and F329 Series ensures a harmonized workflow, optimizing your entire liquid filling and stoppering process.

- Enhanced Production Efficiency:

- By automating the stoppering process, our Tray Loader contributes to enhanced production efficiency, minimizing human error and increasing the overall output of your manufacturing facility. This efficiency is crucial for meeting production targets and maintaining a competitive edge in the industry.

- Versatile Application:

- The Tray Loader accommodates various stopper types, making it a versatile solution for a range of pharmaceutical, cosmetic, or liquid product manufacturing processes. Its flexibility ensures compatibility with different container sizes and stopper specifications.

Invest in the reliability and

- Reliable Stoppering System:

Cozzoli, Capping and Closing Machines, Pharmaceutical, Syringe Filling Machines