Urgent: Final Deadline Approaching for Pharmaceutical Manufacturers

The Drug Supply Chain Security Act (DSCSA) final enforcement deadline is approaching fast. Is your pharmaceutical company fully compliant with the latest FDA serialization requirements? Non-compliance penalties can reach up to $500,000 per violation.

Request a Free Compliance Assessment →

What Is DSCSA Serialization and Why It Matters Now

The Drug Supply Chain Security Act establishes a complete track-and-trace system for prescription medications in the United States. The law requires every pharmaceutical package to have a unique, machine-readable identifier that follows it throughout the supply chain.

The Business Impact of Non-Compliance:

- FDA enforcement actions and substantial financial penalties

- Product seizures and distribution delays

- Loss of distribution rights in the U.S. market

- Reputational damage with customers and partners

- Competitive disadvantage as compliant companies gain market share

2025 DSCSA Serialization Requirements: What You Must Implement

The FDA has established these critical requirements that all pharmaceutical manufacturers must meet:

1. Product-Level Serialization

- Unique Product Identifier: Each package must have a standardized, unique identifier

- 2D Data Matrix Barcode: Must contain the National Drug Code (NDC), serial number, lot number, and expiration date

- Human-Readable Format: Information must also be printed in text format

2. Data Exchange Requirements

- Transaction Information: Electronic transfer of product ownership data

- Transaction History: Complete chain of custody documentation

- Transaction Statement: FDA-required compliance verification

- Data Storage: All records must be maintained for a minimum of 6 years

- Electronic Systems: Must be interoperable with trading partners

3. Verification Systems

- Real-Time Verification: Ability to authenticate products within 24 hours

- Suspect Product Protocol: Documented processes for handling potentially compromised products

- Alert System: Mechanisms to notify trading partners of verification failures

Step-by-Step Implementation Guide

Phase 1: Assessment

- Audit Current Systems

- Evaluate existing labeling hardware capabilities

- Assess data management infrastructure

- Review integration points with supply chain partners

- Gap Analysis

- Identify compliance shortfalls

- Determine hardware/software needs

- Calculate implementation budget and timeline

Phase 2: Solution Selection

- Serialization Hardware

- High-resolution printers capable of consistent 2D barcode production

- Vision systems for verification

- Line control systems

- Serialization Software

- Serial number generation and management

- Master data management

- Supply chain communication protocols

- Data storage and accessibility systems

Phase 3: Implementation

- Hardware Installation

- Production line modifications

- Control system integration

- Testing and validation

- Software Deployment

- Database configuration

- User training

- Trading partner connectivity

- System validation

Phase 4: Validation and Compliance

- Performance Qualification

- Testing under production conditions

- Line efficiency measurement

- Error detection and handling

- Regulatory Documentation

- Compliance protocols

- Standard operating procedures

- Audit-ready documentation

Case Study: Pharmaceutical Manufacturer Achieves Compliance in 90 Days

A mid-sized pharmaceutical company manufacturing injectable medications faced significant challenges with the approaching DSCSA deadline. Their existing systems couldn’t support serialization requirements, and they risked FDA penalties.

The Challenge:

- 12 production lines requiring serialization

- Limited IT infrastructure

- Tight timeline of 4 months to compliance

Our Solution:

- Comprehensive compliance assessment

- Turnkey serialization implementation

- Validated system integration

- Staff training and support

The Results:

- Full DSCSA compliance achieved in under 90 days

- Zero production disruption during implementation

- 99.8% serialization accuracy on first validation

- Avoided potential FDA penalties exceeding $2 million

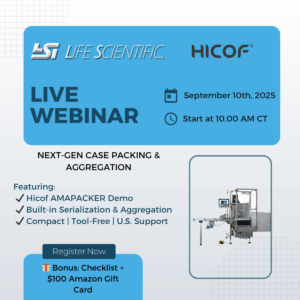

LSI’s Pharmaceutical Serialization Solutions

Our turnkey solutions make DSCSA compliance straightforward and cost-effective:

Hardware Solutions

- Retrofittable Systems: Compatible with existing production lines

- High-Speed Compatible: Maintain production efficiency

- Multiple Packaging Types: Solutions for bottles, blisters, vials, cartons, and cases

Software Platforms

- Cloud-Based Data Management: Secure, 21 CFR Part 11 compliant

- Supply Chain Integration: Seamless data exchange with partners

- Real-Time Monitoring: Continuous visibility across operations

Professional Services

- Compliance Consulting: Expert guidance on regulatory requirements

- Validation Support: Comprehensive qualification documentation

- Training Programs: Ensure your team understands compliance obligations

- Ongoing Support: 24/7 technical assistance

Don’t Risk FDA Penalties – Get Compliant Today

The final DSCSA enforcement deadline leaves no room for delay. Our pharmaceutical serialization experts can assess your specific needs and develop a tailored compliance roadmap.

Phone:

800-829-5741

Email: support@lsi1.com

Frequently Asked Questions about Serialization Requirements / Serialization Compliance

Q: What are the penalties for DSCSA non-compliance?

A: Penalties can include fines up to $500,000 per violation, product seizures, and distribution restrictions.

Q: How long does serialization implementation typically take?

A: For most manufacturers, a complete implementation takes 4-6 months, depending on the complexity of production lines and existing systems.

Q: Can existing production lines be retrofitted for serialization?

A: Yes, our solutions are designed to integrate with existing production equipment, minimizing capital investment.

Q: What ongoing costs should we anticipate after implementation?

A: Typical ongoing costs include software licensing, data storage, system maintenance, and periodic validation activities.

Q: How do we validate our serialization system for FDA compliance?

A: Our validation package includes IQ/OQ/PQ protocols, performance testing, and comprehensive documentation to satisfy regulatory requirements.