Very simple and common Labeling machine issues cost pharmaceutical manufacturers thousands of dollars in downtime, wasted materials, and compliance risks. A single misaligned label can trigger a batch rejection. Understanding the root causes of labeling equipment failures helps production teams respond quickly and maintain consistent output.

This guide covers the most frequent labeling machine issues, their causes, and practical solutions to get your packaging line back on track.

Label Misalignment and Poor Registration

Label misalignment ranks among the top complaints in pharmaceutical packaging operations. When labels wrap crooked or land off-center on vials and containers, the entire batch becomes suspect.

Common causes:

- Worn or damaged guide rollers

- Incorrect label sensor positioning

- Uneven web tension

- Container handling inconsistencies

How to fix it:

Start by inspecting the label path from unwind to application. Check guide rollers for wear marks or debris buildup. Adjust the label sensor to detect the gap or eye mark consistently. Fine-tune web tension settings—too loose causes wandering, too tight causes stretching.

For container-related misalignment, verify that the infeed starwheel and timing screws match your container dimensions. Even a 1mm variance throws off label placement.

Label Wrinkling and Bubbling

Wrinkled labels compromise both aesthetics and barcode readability. Air bubbles trapped beneath the label surface create scanning failures at downstream verification stations.

Root causes include:

- Excessive adhesive or improper adhesive type

- Label stock incompatible with container material

- Application roller pressure set incorrectly

- Static electricity buildup on film labels

Solutions:

Match your label adhesive to the container surface. Glass, plastic, and coated surfaces each require different adhesive formulations. Increase application roller pressure gradually until wrinkles disappear. Install ionizing bars to neutralize static on film-based label stock.

Temperature also affects adhesive performance. Cold containers straight from washing or sterilization need time to reach room temperature before labeling.

Label Feeder Jams and Misfires

Feeder jams halt production instantly. Repeated misfires indicate a mechanical or material problem that won’t resolve itself.

Why feeders jam:

- Label die-cut quality issues

- Matrix stripping failures leaving adhesive residue

- Worn feed rollers losing grip

- Label stock humidity absorption

Troubleshooting steps:

Examine your label rolls for die-cut inconsistencies. Incomplete cuts or excessive adhesive bleed cause labels to stick together or tear during dispensing. Replace worn peel plates—a dull edge won’t separate labels cleanly from the liner.

Store label stock in climate-controlled conditions. Paper labels absorb moisture and swell, changing their dimensions enough to cause feeding problems.

Print Quality Degradation

Pharmaceutical labels require crisp, scannable barcodes and legible text for regulatory compliance. Faded printing, smeared ink, or inconsistent print density creates serious traceability gaps.

Typical causes:

- Printhead contamination or damage

- Ribbon wrinkle or incorrect tension

- Substrate incompatibility with print method

- Incorrect print speed settings

Corrective actions:

Clean thermal printheads daily using manufacturer-approved cleaning cards or swabs. Inspect for pixel burnout—dead pixels leave white lines in printed text. Verify ribbon tension matches your print speed; faster speeds need tighter ribbon control.

Test print quality on the actual label stock you’re running. Coated and uncoated materials behave differently under thermal transfer printing.

Sensor Detection Failures

Modern labeling machines rely on sensors to detect label gaps, product presence, and print verification. When sensors fail or give false readings, the entire system loses synchronization.

Sensor problems stem from:

- Contamination on sensor lenses

- Incorrect sensitivity settings

- Ambient light interference

- Label stock changes without sensor recalibration

Resolution approach:

Clean all sensor lenses with non-abrasive wipes. Adjust sensitivity settings when switching between clear, opaque, or reflective label stocks. Shield sensors from overhead lighting that might interfere with optical detection.

Document your sensor settings for each product configuration. This eliminates guesswork during changeovers.

Inconsistent Label Dispensing Speed

Speed variations cause labels to apply early or late on moving containers. This timing mismatch results in placement errors even when all other settings are correct.

Contributing factors:

- Drive belt slippage

- Servo motor calibration drift

- Encoder wheel contamination

- PLC timing parameters

How to address it:

Inspect drive belts for glazing or cracking. Replace belts showing wear before they fail completely. Clean encoder wheels that track label web movement. Verify servo motor parameters match your current production speed requirements.

Run calibration routines after any mechanical maintenance. Small changes in belt tension or roller diameter affect dispensing timing.

Web Tension Problems

Proper web tension keeps labels tracking straight and dispensing consistently. Too much tension stretches labels and causes premature wear on machine components. Too little tension allows wandering and inconsistent feeding.

Tension issues arise from:

- Brake system wear on unwind spindles

- Dancer arm adjustments incorrect

- Label roll core diameter changes

- Splice tape affecting roll balance

Tension management:

Calibrate your tension control system using a tension meter rather than relying on visual assessment. Adjust brake pressure as roll diameter decreases during production. Inspect dancer arms for smooth, unrestricted movement.

Use consistent core sizes across all label suppliers. Different core diameters require brake adjustments that add changeover time.

Adhesive Residue Buildup

Adhesive contamination on rollers, guides, and sensors degrades machine performance over time. Residue attracts dust and debris, compounding the problem.

Prevention and cleaning:

Schedule regular cleaning intervals based on your production volume and label stock characteristics. Use adhesive removers compatible with your machine’s roller materials. Avoid abrasive tools that damage precision surfaces.

Consider upgrading to labels with cleaner die-cuts and less adhesive bleed. Higher-quality label stock reduces maintenance burden.

Preventive Maintenance for Labeling Equipment

Reactive troubleshooting addresses immediate problems but doesn’t prevent recurrence. A structured preventive maintenance program reduces unplanned downtime and extends equipment lifespan.

Essential maintenance tasks:

- Daily: Clean sensors, inspect label path, verify print quality

- Weekly: Check belt tension, clean rollers, inspect wear parts

- Monthly: Lubricate moving components, calibrate sensors, review error logs

- Quarterly: Full mechanical inspection, replace wear items, update software

Document all maintenance activities. Trending your maintenance data reveals patterns that predict failures before they happen.

When to Call for Service Support

Some labeling machine issues require factory-trained technicians. Electrical faults, PLC programming errors, and structural damage exceed typical in-house capabilities.

Contact your equipment supplier when:

- Error codes persist after standard troubleshooting

- Mechanical components need precision adjustment or replacement

- Software updates or parameter changes are required

- Production quality remains inconsistent despite maintenance efforts

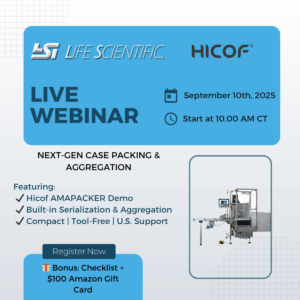

Life Scientific, Inc. has represented leading pharmaceutical labeling equipment manufacturers since 1992. Our team connects you with the right labeling solutions for vials, syringes, ampoules, and containers—backed by technical expertise and responsive service support.

Need help with your labeling line? Contact Life Scientific today to discuss equipment options, troubleshooting support, or schedule an on-site consultation.