- A liquid filling machine is a specialized industrial equipment designed to accurately dispense and fill containers with liquid products. These machines are commonly used in various industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and more. The primary purpose of a liquid filling machine is to streamline and automate the filling process, ensuring precision, efficiency, and consistency in the volume of liquid dispensed.

Key features of a typical liquid filling machine include:

- Accuracy and Precision: Liquid filling machines are engineered to deliver precise and accurate measurements of liquid to ensure consistency in product quality and to minimize waste.

- Versatility: These machines are versatile and can handle a wide range of liquid viscosities, from thin liquids like water to thicker substances such as oils or syrups.

- Adjustability: Liquid filling machines often come with adjustable settings to accommodate different container sizes and fill volumes, allowing for flexibility in production.

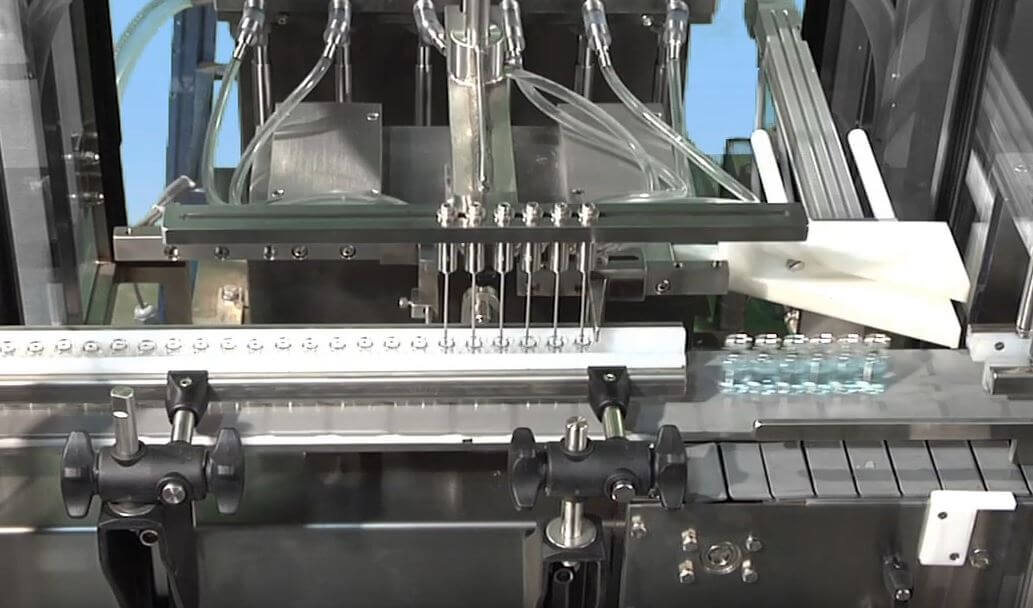

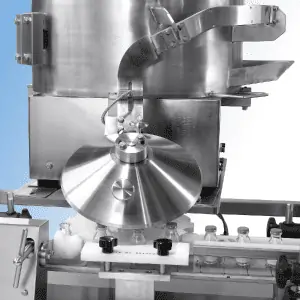

- Automation: Many liquid filling machines are fully or semi-automated, reducing the need for manual labor and increasing production efficiency. Automated systems can include features such as bottle indexing, capping, and labeling.

- Hygiene and Cleanability: Liquid filling machines are designed with materials that meet hygiene standards, making them suitable for use in industries with strict cleanliness requirements, such as pharmaceuticals and food production. They are often easy to clean and maintain.

- Dosing Mechanisms: These machines can employ various dosing mechanisms, such as piston fillers, gravity fillers, peristaltic pumps, or rotary fillers, depending on the specific requirements of the liquid being dispensed.

- Container Handling: Liquid filling machines are equipped with mechanisms to handle different types of containers, including bottles, jars, vials, and cans.

- Control Systems: Advanced liquid filling machines may have electronic control systems that allow for precise adjustments, monitoring, and data recording.

- Safety Features: Safety is a priority in industrial settings. Liquid filling machines may include features such as emergency stop buttons, safety guards, and compliance with industry safety standards.

Cozzoli, Pharmaceutical, Vial Filling Machines