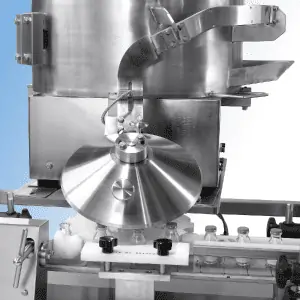

S350 – Labeling Machine

- Glass Bottle Labeling

- Plastic Bottle Labeling

- Securitainers Labeling

- Vial Labeling

- Outputs up to 300 c.p.m

- ‘Auto / teach’ label length facility

- Quality Assured product

- Color touch screen H.M.I.

- Both paper and clear self-adhesive labels

Generally installed in-line, the S350 transports the containers along a conveyor and spaces them, using a scroll feed, before they enter the labeling station. The label is applied and then immediately the container comes under control of the applicator belt, resulting in precise registration and crease-free application.

Features:

- Compact cGMP Design

- ‘Auto-teach’ label length facility

- Digital scales for rapid container changeover

- Positive accept security system

- Fully validated security system with Critical Device Checking

- Minimal change parts

- High performance stepper motor for label web drive

- In Process Control – system verification without production stoppages

- Accurate label placement

- Stainless steel 304 finish

- Siemens or Allen Bradley PLC control system

- Label coding options

- Auto-reject system for both incorrect label data and missing label detection with reject verification

- Touch screen HMI with run mode and set up mode (key switch access) facility

- Counter package with full count reconciliation

- End of web detection

- Applicator belt cassette system with tool-less changeover

Options:

- Validation documentation and implementation package

- Recipe system for up to 100 products

- 3 level password access

- Printout facility

- Continuous label supply via the Easisplice 470 unit

- Queue switch control

- Vision Systems for OCV / OCR / barcode

- Rotary infeed & outfeed tables

- Left and Right hand option available