The ultimate solution for precise powder dispensing in space-conscious environments.

- Engineered with a fully sealed product pathway that eliminates cross-contamination risks

- Intuitive controls allow operators to fine-tune fill volumes during active production

- Versatile design accommodates various powder densities and container sizes

- Choose between single or dual filling stations based on your throughput needs

- Minimal footprint maximizes valuable workspace while maintaining industrial capabilities

Trusted by pharmaceutical labs, food manufacturers, and cosmetic producers who demand meticulous accuracy without industrial-scale equipment. Upgrade your filling process without upgrading your facility size.

Technical Specifications

Overview

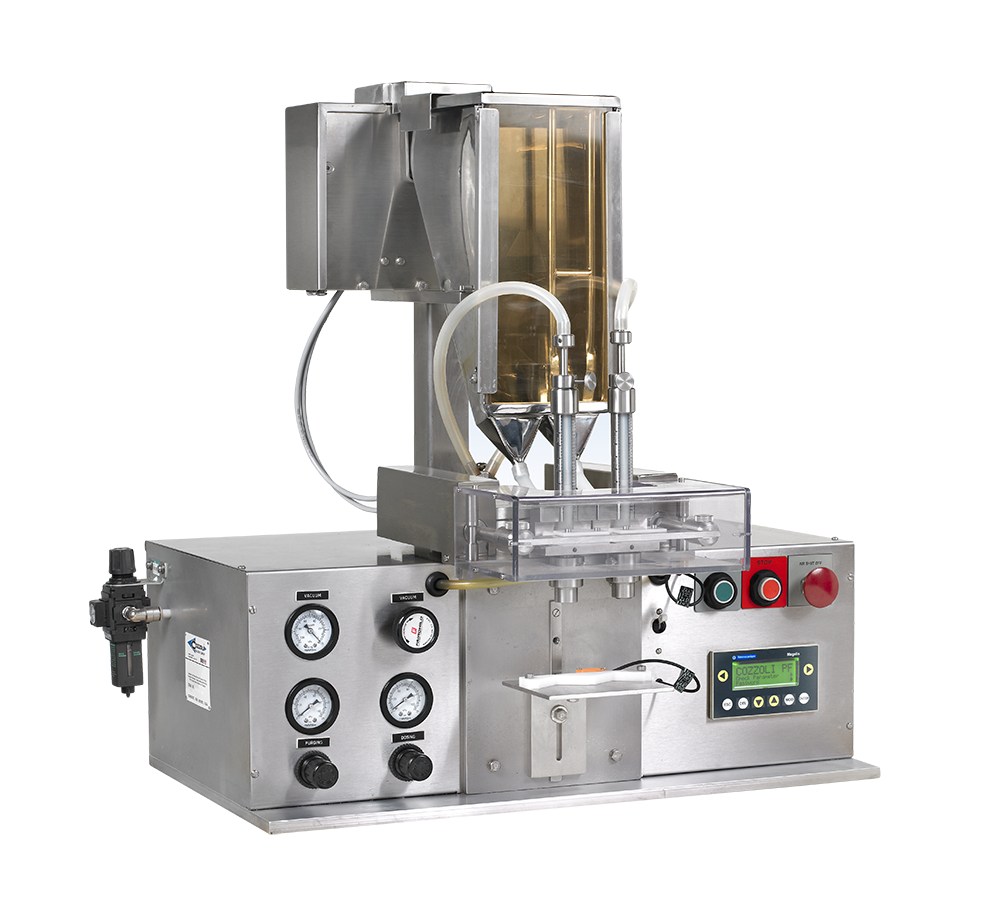

The Tabletop Powder Filling Machine delivers precision auger filling for laboratories and small-scale production facilities. This compact system provides industrial-grade performance within a space-conscious footprint, ideal for businesses requiring meticulous powder dispensing without investing in full-scale industrial equipment.

Core Technology

The machine features a precision-engineered auger mechanism ensuring consistent filling across various powder densities. The system employs volumetric filling technology where auger rotation controls powder dispensed into each container.

Key Technical Features

Enclosed Product Pathway System

- Fully Sealed Design: Enclosed powder path eliminates environmental contaminants

- Non-Abrading Components: Material-contact surfaces manufactured from 316L stainless steel or pharmaceutical-grade polymers

- Zero Cross-Contamination: Complete product isolation prevents batch mixing

- Tool-Free Disassembly: Quick-disconnect components enable rapid cleaning and changeovers

Precision Control Mechanisms

- Fill Accuracy: ±1% filling accuracy across operational range

- Microprocessor Control: Digital controls maintain consistent fill weights through algorithmic monitoring

- Real-Time Adjustment: On-the-fly volume modifications without stopping production

- Variable Speed Control: 10-100% speed adjustment in 1% increments for optimal powder processing

Technical Specifications

Performance Parameters

| Parameter |

Specification |

| Fill Accuracy |

±1% across operational range |

| Production Speed |

Up to 30 containers per minute (single station) |

| Production Speed |

Up to 60 containers per minute (dual station) |

| Min. Fill Volume |

0.5 grams (varies by powder density) |

| Max. Fill Volume |

500 grams (varies by powder density) |

| Powder Compatibility |

Fine to medium-coarse powders (10-500 micron particle size) |

Precision Control Algorithms

Advanced auger control algorithms compensate for variations in powder density, flow characteristics, and environmental conditions:

- Pre-Feed Optimization: Automatic adjustment of feed rates based on hopper levels

- Tail Compensation: Intelligent cut-off timing to prevent overflow

- Vibration Management: Programmed vibration patterns for complete container filling

- Temperature Monitoring: Ambient temperature compensation for consistent accuracy

Modular Configuration Options

Customizable design architecture meets specific production requirements.

Available Modules

- Single or Dual Filling Stations: Select based on throughput needs

- Hopper Capacities: Standard (5L), Extended (10L), or Mini (2L)

- Auger Sizes: Multiple geometries for different powder characteristics

- Container Handling: Manual placement or semi-automated indexing conveyor

- Weighing Integration: Optional in-line check-weighing with feedback control

- Vacuum De-Dusting: Add-on for clean room applications

Compliance and Certification

Engineered to meet industry standards for quality, safety, and regulatory compliance:

- CE Certification: Compliant with relevant European directives

- FDA Compliance: All product contact materials meet FDA requirements (21 CFR)

- cGMP Design: Constructed following current Good Manufacturing Practices

- ISO 9001: Manufactured under ISO 9001:2015 quality management system

- IP54 Protection: Dust and splash protection for electrical components

- IQ/OQ Documentation: Available installation and operational qualification packages

Application Versatility

Suitable for multiple industries and applications:

Industry Applications

- Pharmaceuticals: Research laboratories, clinical trial batches, small-scale production

- Nutraceuticals: Vitamin supplements, protein powders, herbal formulations

- Food Processing: Spices, flavor enhancers, bakery ingredients

- Cosmetics: Face powders, bath products, powder foundation

- Chemicals: Laboratory reagents, catalyst powders, analytical samples

- Research & Development: Formula testing, sample preparation, prototype production

Maintenance and Support

Maintenance Features

- Tool-Free Disassembly: Complete disassembly for cleaning in under 5 minutes

- CIP Compatible: Optional Clean-In-Place connections for automated washing

- Wear Indicators: Visual markers on high-wear components

- Accessible Design: All maintenance points designed for easy access

Support Package

- Warranty: 24-month manufacturer warranty

- Technical Support: Remote assistance via secure video connection

- Spare Parts Kit: Essential maintenance parts included with purchase

- Documentation: Operation manual, maintenance guide, and spare parts catalog

- Training: On-site or virtual operator and maintenance training