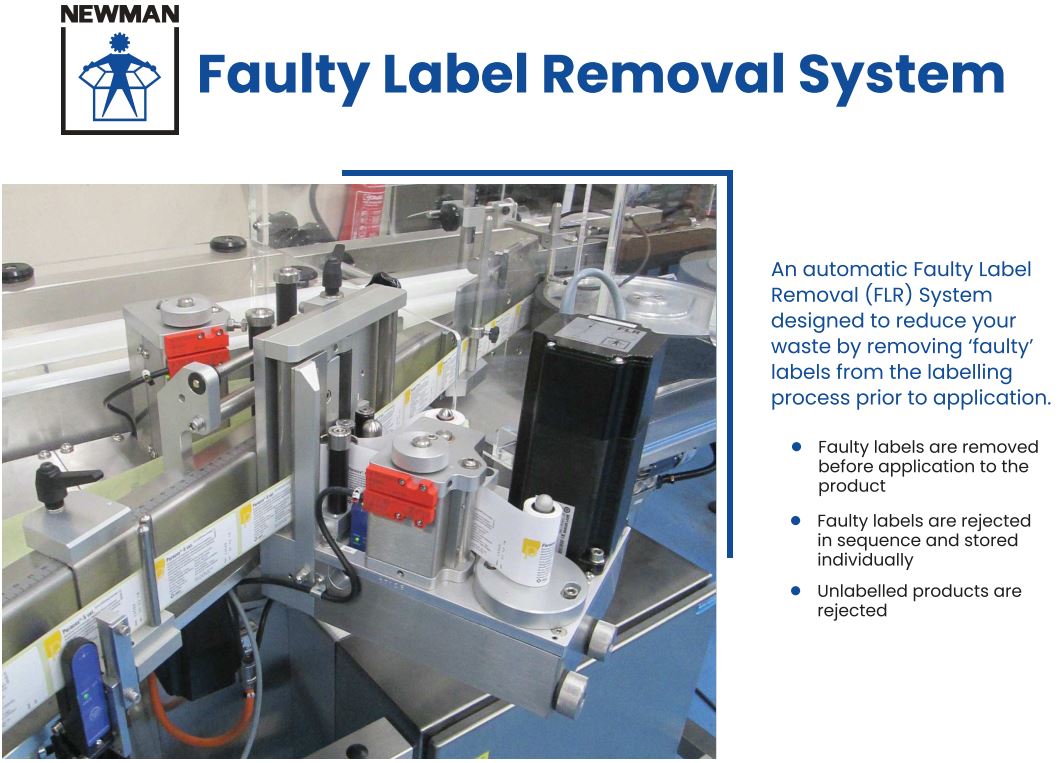

The Newman Faulty Label Removal (FLR) System is designed to identify and remove faulty labels before they are applied to products. This system reduces waste by ensuring only good labels are used, eliminating the need for manual de-labelling and preventing spoiled products. Faulty labels are rejected in sequence and stored separately, allowing for full reconciliation and monitoring of print quality. The FLR system operates at speeds of up to 500 labels per minute and works with both transparent and opaque labels. It features a retractable design for easy maintenance, label stripper plates, web position compensators, and sensors for label rejection and paper web break security. Constructed from Type 304 stainless steel and anodised aluminium, the system is durable and reliable. It is available as an option on Newman labelling models and complies with regulatory guidelines.

Labeling Systems, Newman Labelling Systems

Newman Faulty Label Removal (FLR) System – Automate Label Quality Control

The Newman Faulty Label Removal (FLR) System automatically removes faulty labels before application, reducing waste and improving efficiency. It ensures only good labels are applied to products, with faulty labels stored sequentially for easy reconciliation.

Skip to content

Skip to content